[ad_1]

Solid-state metal 3D printing specialist Fabrisonic has leveraged its patented Ultrasonic Additive Manufacturing (UAM) process to successfully merge different amorphous alloys into multi-metal cladding.

Working as part of a NASA SBIR study, the company deployed ultrasonic energy rather than a conventional laser-based 3D printing method to combine dissimilar corrosion-resistant alloys. Using its proprietary fabrication technique, Fabrisonic was able to join the metals to crystalline substrates, without destroying any of their beneficial properties.

The resulting metallic mixtures featured enhanced strength, and corrosive-resistant qualities to ordinary crystalline alloys, which could make them well-suited to future cladding applications in the aerospace industry.

Fabrisonic’s Ultrasonic Additive Manufacturing technique

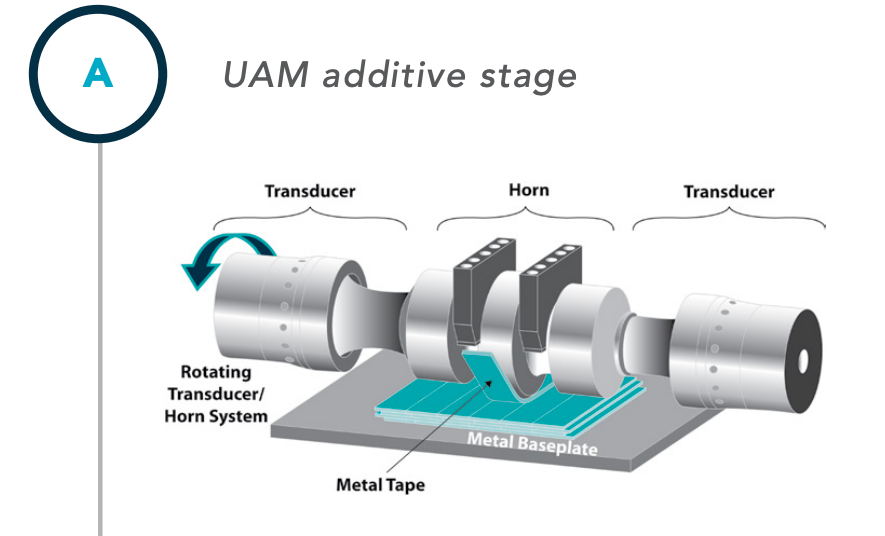

Fabrisonic’s UAM technology is a hybrid metal 3D printing process, which ultrasonically welds a succession of metal tapes into a 3D shape. The method operates at a low temperature, which enables dissimilar materials such as electronics, to be embedded into metal alloy structures.

As the metal object is built up, a CNC machine can also be used to finish its internal and external surfaces, which allows users to create more detailed shapes than conventional metal 3D printing processes. Since the company patented its UAM printing technique in 2017, it has gone on to release its SonicLayer 1200 machine, which also features its UAM technology.

In an attempt to find new applications for its patented 3D printing technique, Fabrisonic has established partnerships with a number of U.S. government research groups in recent years. Working with Oak Ridge National Laboratory (ORNL), the company deployed UAM to 3D print control plates for ORNL’s High Flux Isotope Reactor (HFIR).

Fabrisonic has also forged a close relationship with NASA, and their co-developed 3D printed heat exchanger devices passed spaceflight quality control tests in 2018. More recently, the firm partnered with optical sensor specialist Luna Innovations on a fabricated sensor project for NASA. The program aims to gather data on cryogenic fuel pipes for rocket test stands at the Stennis Space Center.

In NASA and Fabrisonic’s latest collaboration, the latter has further developed its UAM process to print combined metal claddings, which may have aerospace applications in future.

Taking better advantage of amorphous metals

Amorphous metals, or Bulk Metallic Glasses (BMGs) are created by cooling alloys very quickly, bypassing the crystallization phase of solidification. As a result, the materials have a uniquely disordered structure, which provides them with a higher level of strength than conventional crystalline alloys.

BMGs can also sustain larger reversible deformations than other metals, and their lack of long-range periodicity makes them more corrosion-resistant too. Although amorphous metals clearly have advantageous manufacturing features, they have previously proved difficult to join with other materials, and to print in thicker layers.

Working with serial NASA-collaborator LM Group Holdings (LMGH), Fabrisonic attempted to overcome these limitations, by using its UAM 3D printing process to merge amorphous metals with other alloys. The companies proved the feasibility of the process by joining several different amorphous alloys, and studying the reaction in order to better understand their interface compositions.

During testing, the team found that UAM’s low temperature enabled dissimilar metal alloys to be joined with little to no inter-metallic formation, and without diminishing their high-strength characteristics. The companies also discovered that multiple passes could be used to add more metals, which in turn, enabled the structure’s thickness to be tailored depending on its end-use application.

According to the paper, low ductility is often an issue with existing crystalline alloys, but given that UAM is compatible with multiple materials, it enables more ductile metals to be added to the mix. Similarly, traditional welding techniques had limited BMGs to specific geometries, but evaluations showed that more complex 3D shapes could now be achieved with UAM, and at a lower cost as well.

Overall, in Phase I of the NASA development program, the partners managed to merge crystalline metals such as aluminum, titanium, and steel, yielding parts that with a wall thickness of 1mm. In future, the 3D printing technique could be deployed in the creation of laminate panels for use within heavy equipment, or to insulate oil and gas pipelines.

“LMGH and Fabrisonic can provide products and services that are a generational leap ahead of the current state-of-the-art,” stated the companies in their paper. “Significant advantages in base material protection, service life extension and application efficiency increases, all provide an arsenal of market levers.”

Fabrisonic’s findings are detailed in its white paper titled “Manufacturing Amorphous Wear and Corrosion Resistant Cladded Surfaces using Ultrasonic Additive Manufacturing (UAM),” which was published via the company’s website, and authored by Mark Norfolk, President of Fabrisonic.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

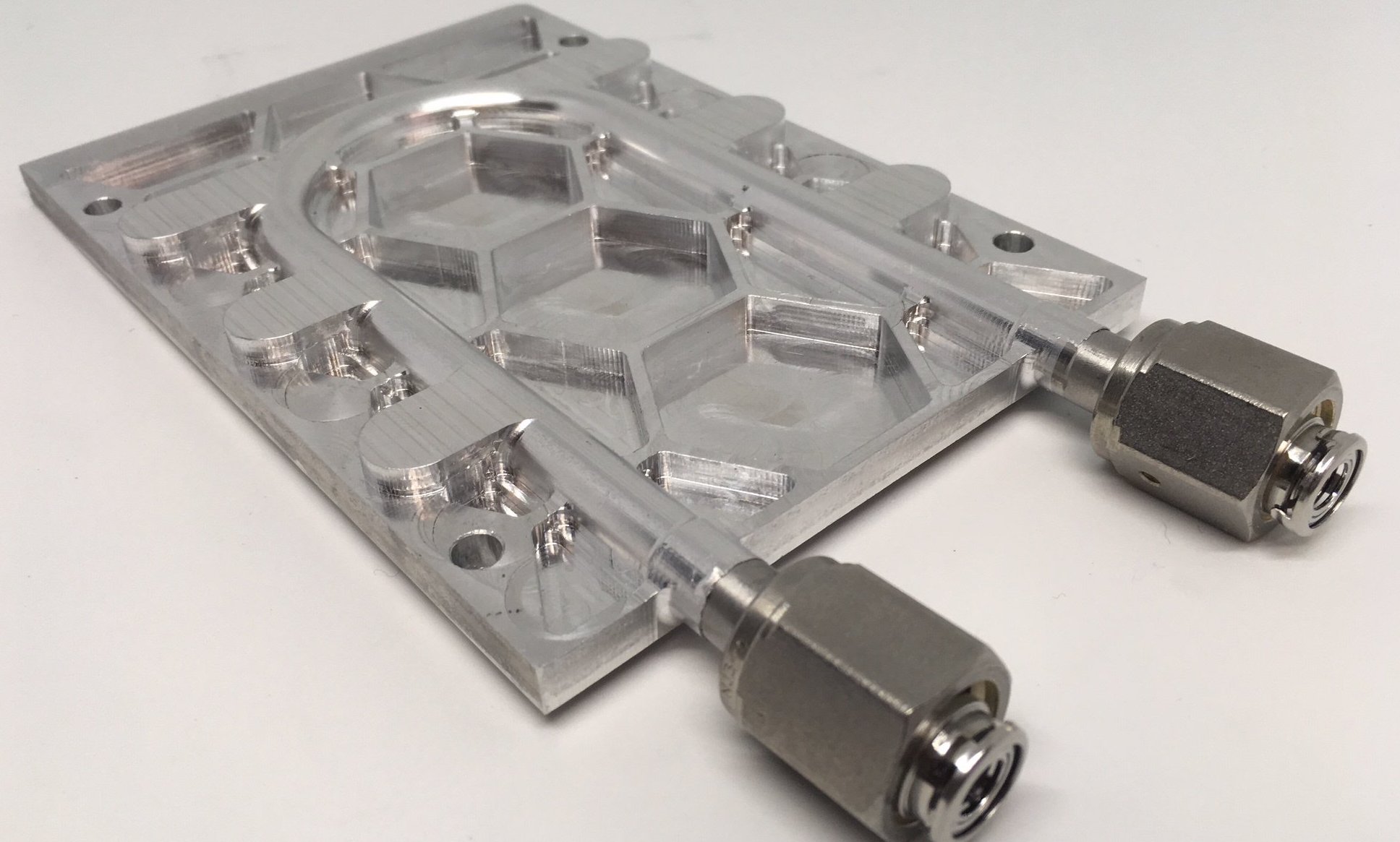

Featured image shows the Fabrisonic SonicLayer 7200 UAM system used within the study. Photo via Fabrisonic.

[ad_2]

Source link