[ad_1]

Samsung’s gate-all-around transistor design won’t arrive in processors until 2022.

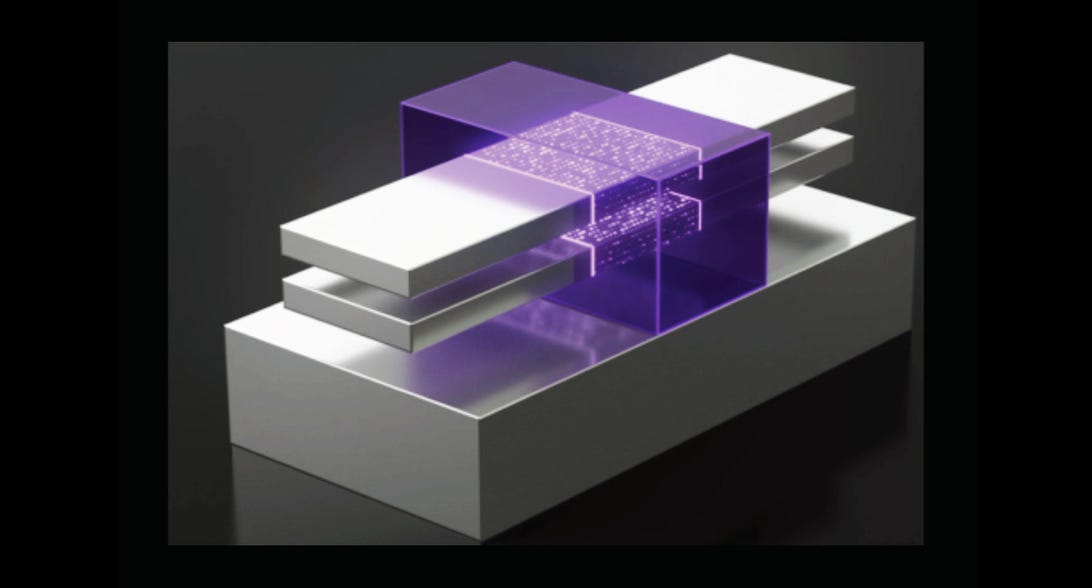

Samsung Foundry

Samsung had planned to start building a faster and more efficient class of processors this year, but the technically difficult shift to a major new design means the chips will arrive in 2022 instead. The Korean electronics giant shared the schedule for the shift in conjunctino with its Samsung Foundry Forum on Wednesday.

The slip means customers that rely on Samsung will have to wait longer to tap into the leading-edge technology. Among the biggest names using the company’s services are phone-chip-designer Qualcomm, server maker IBM and Samsung itself.

The good news for those customers, though, is that Samsung also announced progress in the next generation of manufacturing afterward, a refinement that should arrive in 2025. That should deliver another step forward in chip performance, power efficiency and electronics miniaturization, Samsung said.

Samsung’s top chipmaking rival, Taiwan Semiconductor Manufacturing Co., disclosed a delay to similar technology in August. The schedule slips ease the pressure a little on Intel, which is launching its own foundry business as part of a recovery plan aimed at reclaiming the leadership it lost to TSMC and Samsung.

The processor business is under extreme pressure. With the pandemic boosting PC sales, smartphone usage, and online services run out of data centers, demand for processors has outstripped manufacturing capacity. The chip shortage has hobbled sales of PCs, game consoles, cars and other products reliant on world-spanning electronics supply chains.

Based on Samsung’s conversations with customers, the processor shortage won’t ease until 2022, said Shawn Han, a Samsung Foundry corporate senior vice president, based on Samsung’s conversations with customers. “From our view, it will be lasting another six to nine months, although we are investing, and other foundries suppliers are increasing their capacity,” he said in a briefing ahead of the Samsung Foundry Forum.

Moving to next-generation manufacturing technology is extraordinarily complicated. Chips are made of billions of electronic components called transistors, each vastly smaller than a speck of dust. Chip fabrication plants, called fabs, etch the circuitry patterns on silicon wafers with a process requiring dozens of steps that take months.

Progress comes by miniaturizing transistors so more can be squeezed onto a chip, increasing their speed and decreasing their power consumption. Samsung’s next-gen process, which it calls 3GAE, employs a technique called gate all around (GAA). It’s an early version of the technology.

In 2023, Samsung expects to reach high production volume with a more mature version called 3GAP. The 3 in the name refers to the 3-nanometer measurement that, although no longer directly linked to the dimensions of chip electronics, serves as a label for progress in manufacturing methods.

Then in 2025, the company plans to move to a second, more advanced gate-all-around technology it calls 2GAP. That manufacturing method will be the first of Samsung’s 2nm generation.

As chips get more complex, they often get more expensive, too, which is why many chip buyers are sticking with older, cheaper manufacturing processes from companies like GlobalFoundries.

But Samsung believes it can make the new manufacturing processes financially alluring to customers.

“Even though GAA is a difficult technology, We will still strive to lower the cost per transistor,” said Moonsoo Kang, head of Samsung’s Foundry Strategy Team. “That trend will continue.”

[ad_2]

Source link