[ad_1]

Food manufacturers and producers are responding to Canada’s food waste epidemic with technology. Using the latest in tech, many food producers have been able to minimize food waste.

To call it an epidemic isn’t an exaggeration. According to a report by Second Harvest, 58 per cent of all food produced in Canada is lost or wasted. Food suppliers across verticals are taking steps to save some of this wasted food.

Outcast Foods has launched five single ingredient powders that are manufactured by upcycling food leftovers. Photo © Outcast Foods

Outcast Foods

One of those companies is Nova Scotia’s Outcast Foods. They collect unwanted fruits and vegetables from farmers and distributors across Canada, and transform them into nutrient dense powders. They use technology to process their unique leftovers, so they can provide quality product to consumers with little-to-no waste.

“It’s a part of the food waste continuum. Different food is wasted throughout the process, starting with the farmers food that doesn’t get selected by the distributors simply because the harvest is the wrong colour,” said Dr. Darren Burke, CEO of Outcast Foods. “We save the fruit and vegetables, including product that has gone bad. We get rid of any bacteria through our manufacturing process, and hold on to the nutrients.”

When Outcast Foods was developing their manufacturing process they realized that it was a complex issue that needed a complex solution.

“We developed a machine learning protocol that can take all the information about the product—its size, shape, how old it is and the distance of the farm—and figure out if it makes sense to bring it to our facilities,” said Dr. Burke. “Once it’s in our facility, we developed a unique process to get it from ingredient to powder.”

Outcast Food’s manufacturing process starts with a washing phase, where a unique organic acid is sprayed on the vegetables and fruits, eliminating any bacteria. Then it moves to the size reduction phase, where it is dehydrated and mulled into a fine, free-flowing powder.

Outcast Food’s unique manufacturing process in their facilities have caught the attention of heavyweight companies like Nestle and Riverside Foods, as both companies have partnered with the East Coast company as suppliers.

Loop Mission

Another company that is using technology in their manufacturing process to help reducing food waste is Loop Mission. A juicing company based out of Montreal, Loop saves food waste at its source and aims to maintain a net positive result throughout their whole manufacturing process. They teamed up with one of Quebec’s largest fruit and vegetable distributors, Courchesne Larose, who provides them with fruits and vegetables that would have been thrown out.

“Courchesne Larose gives us their misshapen produce, and they get a percentage of our sales,” said Pascale Larouche, Loop Missions’ public relations lead. “Our co-founder David Côte saw just how much they were going to throw away and thought, ‘we need to do something will all this waste.”

Loop Mission is actually housed within the distribution facility and uses produce to create fruit and vegetable juice, smoothies, probiotic sodas and a newly added gin, thanks to Krispy Kernels chips, who donated their potato scraps. Not only do they take food waste from other companies, but also are net positive within their own company, giving any residential pulp from their produce to a local vegan dog food manufacturer.

When it comes to their own product, Loop Mission uses the latest in technology to ensure their juices are not going to waste, by extending their shelf-life. Loop Mission’s juices and smoothies are unpasteurized, which means they have a shorter shelf-life than their pasteurized counterpart. In order to ensure their juices aren’t contributing to food waste, they use high pressure processing (HPP). This processing technology helps extend their shelf life to 66 days, where unpasteurized juice has a shelf-life of only a few weeks.

HPP is a technique that takes place after the product is in its final package. The high pressure and cold temperatures help deactivate the flora or bacteria present in the food product.

“Instead of pasteurizing we use HPP,” said Larouche. “It not only extends the shelf-life but also doesn’t remove any nutrients” from the product.

While Loop Mission and Outcast Foods are combating food waste within the processing of food waste, B.C.-based NEXE are making their impact on food waste reduction through 3D printers.

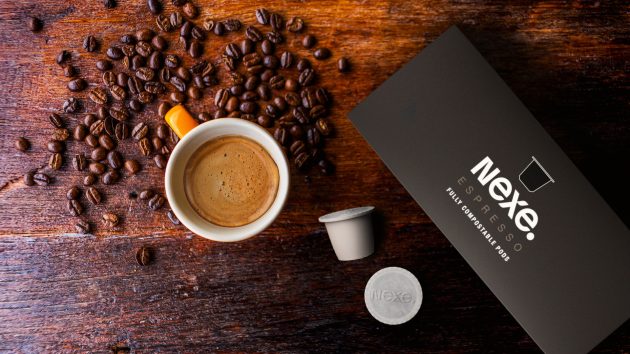

These espresso pods by NEXE Innovations fully breaks down in 30 days. Photo © NEXE Innovations

NEXE Innovations

Scientific advisor Zac Hudson and NEXE Innovations developed a compostable coffee pod to target single-use packaging. A third of consumer’s plastic consumption is from single-use packaging like yogurt cups, cosmetics and coffee pods.

The biodegradable coffee pods come pre-packed with sustainable coffee, under the XOMA Superfoods brand. The pod is made from a combination of plant fibre, compostable polymers, and other compostable materials, with a bamboo casing.

“We develop compostable alternatives for traditional plastic packaging,” said Hudson. “Sixty billion pods are discarded every year. That’s 13,000 a minute. Our pod is corn based and takes about 35 days to completely break down.”

When food or coffee pods sit in a landfill, methane is released into the atmosphere, a greenhouse gas 25 times more potent than carbon dioxide. Not only are they helping reduce the plastic waste and carbon footprint of coffee pods, but also take care to use sustainable methods when making prototypes through the 3D printer.

“We use polylactic acid, which is the most common filament for a 3D printer, which has allowed us to eliminate the need for stainless steel moulds,” said Hudson. “Processing steel is expensive, time consuming and carbon-intensive.”

Good to Go

Food waste isn’t only present at the grower and distribution level in the food industry. It is prevalent in grocery stores and restaurants across Canada. In fact, 86 per cent of all food waste in Canada takes place in the food service industry. American start-up Good to Go is looking to help restaurants and grocers cut back on their food waste.

Launched in Canada in July 2021, Good to Go uses apps to connect the restaurant industry to their consumer. Restaurants, bakeries and grocery stores can sign-up online to sell surprise packages directly to consumers at the end of the day.

“The surplus food can be picked up in “surprise bags,” which creates a win-win-win situation,” said Sam Kashani, country manager at Good to Go. “The store or restaurant wins because they don’t throw out the food; consumer wins because they get food at a good price; and the planet and environment win because of the reduction in food waste.”

With food waste responsible for eight per cent of negative impact to the environment, Good to Go believes that reducing food waste is the number one action the restaurant industry can take to help fight climate change. They are currently active in 16 countries, and are getting more local businesses signing-up to participate in their movement every day. Within 10 to 15 minutes, business owners can be live on the app and ready to upload their surprise bags.

“Technology has given us access and scale to allow to us inspire everyone to join the fight. It allows us to scale quite quickly and create a connected marketplace. It allows us to communicate,” said Kashani. “We know food waste is unpredictable. When you have an unpredictable model, technology allows us to create a real-time market, which helps minimize the unpredictable nature of the industry.”

Whether food manufactures are combatting the food waste epidemic at the processing level or consumer level, food waste is something that impacts everyone through the supply chain. Using new innovative technology is the right step toward mitigating the effects of food waste in Canada.

This article was originally published in the September 2021 issue of Food in Canada.

[ad_2]

Source link