[ad_1]

Dezeen School Shows: a mission involving the fusion of wood and mycelium is included in Dezeen’s newest faculty present by college students on the New York Institute of Technology.

Also included is a “hypothetical city” created by way of a mixture of hand sketches and AI, and a mission that explores the idea of chainmail.

Institution: New York Institute of Technology

School: School of Architecture and Design

Course: Master of Science, Architecture, Computational Technologies

Tutor: Fadhil Fadhil

School assertion:

“The Master of Science in Architecture, Computational Technologies programme is a two-semester, 30-credit, post-professional grasp’s diploma programme on the New York Institute of Technology.

“It explores the intersection of structure, know-how and innovation, empowering college students to form the way forward for design and building by cutting-edge analysis and sensible software, thereby maximising their employability expertise.

“At New York Tech, architectural training is just not merely about buying data; it is about honing expertise by tackling more and more complicated design challenges that can outline the architectural design subject, taking up a extra interdisciplinary and technologically oriented method.

“Essential expertise acquired within the programme within the first semester embody coding, massive information evaluation, simulations, augmented actuality, computational modelling, machine studying and synthetic intelligence as they relate to structure and sustainability.

“In the second semester, college students take part in design studio actions, together with digital fabrication, robotic building techniques, and the simulation and optimisation of supplies.

“These expertise culminate within the creation of 1:1 prototypes and installations, in addition to real-world subject experiences {and professional} settings, which can embody worldwide exhibitions such because the Venice Biennale and the Salone del Mobile in Milan.

“Nestled within the coronary heart of New York City, alongside Broadway, and simply steps away from Central Park and Columbus Circle, the New York Tech School of Architecture and Design is the one faculty of structure and design within the New York space with totally accredited programmes in each structure and inside design.

“As a end result, the situation of the programme offers college students with a rare alternative to expertise New York City as a dynamic city dwelling lab.

“New York Tech graduates form the largest network of licensed architects in New York State, offering an invaluable source of mentorship, guidance and abundant employment opportunities.”

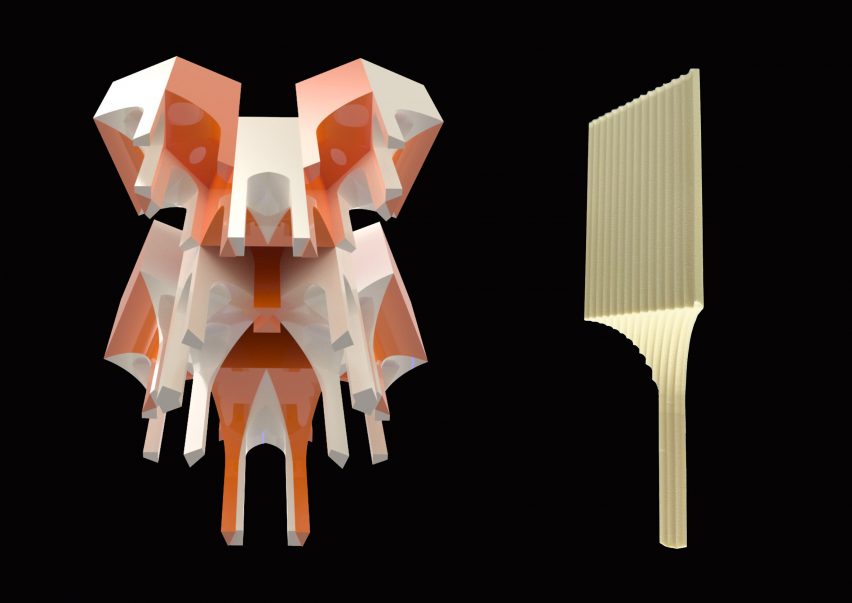

Image 3D Fabrication by Tharoonaskar Baskaran and Arathi Chilla

“Each Foam CNC milled high-density panel exhibits an unorthodox workflow that paperwork and creates a three-dimensional moveable, adaptable and sustainable facade screening gadget from a two-dimensional AI-generated picture.

“The mission explores a doable situation of superior computational design and fabrication methods unravelling the probabilities that emerge from a purely two-dimensional AI-generated picture.

“The model shows the same AI-generated image realised through two different digital modelling and fabrication techniques. The pieces are made from high-density foam.”

Students: Tharoonaskar Baskaran and Arathi Chilla

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

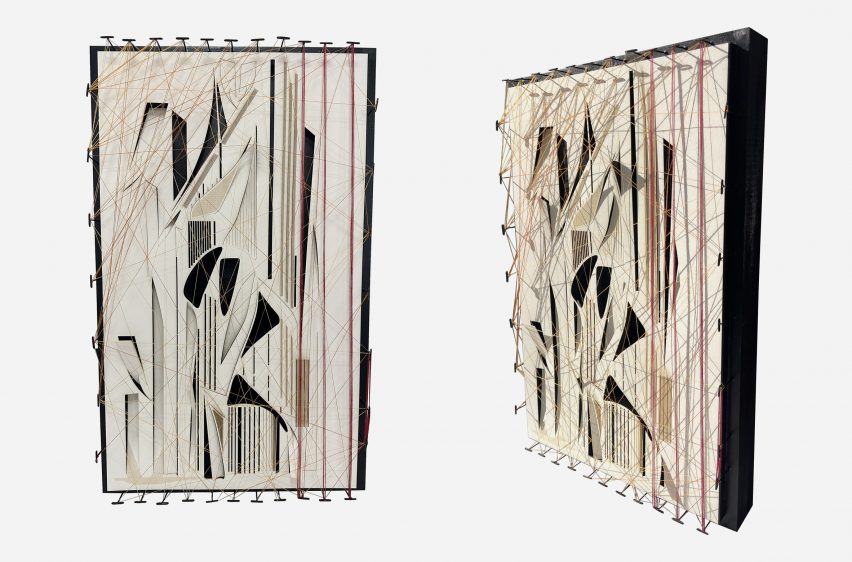

Fragmented City by Mahima Kulkarn

“The product resembles a hypothetical metropolis that’s designed by the negotiation of hand sketches, portray, AI photographs and multimedia fabrication course of.

“The city fragments are expressed through the lines, the masses and strings. The piece is made from PLA 3D printing, milled MDF, laser cut museum board, metal pins and string.”

Student: Mahima Kulkarn

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

Resolution Through Fabrication by Mike Saad

“CNC milled high-density foam panels discover the thought of ‘decision by fabrication’ as the first matter inside the course of robotics and fabrication.

“The course of transforms related geometries or kinds into totally fabricated objects with completely different texture resolutions primarily based on a number of fabrication variables akin to toolpath densities, mill bits sorts and gear sizes.

“The mission explores the idea of 3D decision by CNC milling emphasising the fabrication variables showcased by geometry, instrument paths and gear bits.

“Different combinations of these variables unpack variations of surface finishes while maintaining the autonomy of the original geometry input.”

Student: Mike Saad

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

Chainmail 3D Printing by Karan Patel

“The mission explores the idea of chainmail, which utilises the aggregation of small objects linked by versatile interlocking connections. Such an method permits the technology of versatile material results from the buildup of 3D printing strong objects.

“Practically, the final product could function as a flexible facade or structural system. The piece is made from 3D printed polylactic acid filament.”

Student: Karan Patel

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

Geodesic Dome Kinetic Structures by Jahan Selim

“This mission envisions a geodesic dome construction with a central hinge connection that enables for rotational versatile motion. The node design is essential because it stays probably the most fastened piece within the system.

“The prototype explores the idea of kinetic structures that host flexible fabrics as a stretchable infill between the armatures.”

Student: Jahan Selim

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

Robotic Clay Stamping by Amisha Bavadiya

“This prototype explores the idea of 3D robotic stamping. In this case, clay is used because the reduction materials that receives the stamp whereas being contained inside a wood mould.

“The patterns used to stamp the clay are fabricated on a high-density foam material using 2D CNC profiling operation.”

Student: Amisha Bavadiya

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

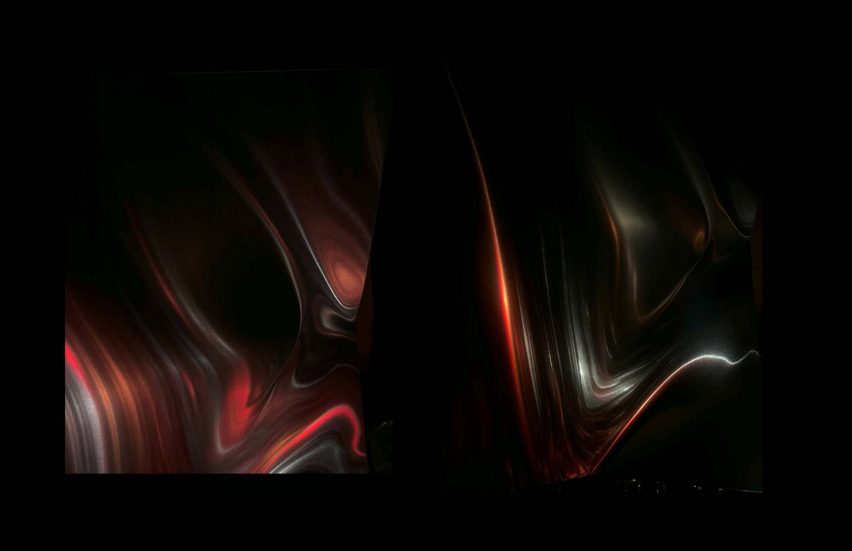

Shadow Reflection by Yashraj Chauhan

“This mission resulted in photographs displaying variations of sunshine and shadow reflections on an aluminium sheet. The course of underwent rigorous testing on a number of gentle situations as they work together with steel sheets from a number of angles responding to explicit steel folds.

“Prototype showing early exploration for a light installation that combines both light and shadow interactions with the folded aluminium sheets.”

Student: Yashraj Chauhan

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

Muqarnas by Robotic Wire Cutting by Arefin Chisty

“This mission culminated in a collection of prototypes displaying a reenvisioned course of of manufacturing the standard elements of Muqarnas structure utilizing CNC milling and robotic wire chopping.

“The mission explores prototypes which can be produced utilizing minimal floor scorching wire chopping operations producing a number of variations of comparable Muqarnas geometries.

“It is an attempt to revive the lost historical craftsmanship through utilising the current highly advanced computational design and robotics fabrication tools.”

Student: Arefin Chisty

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

Urban Densities by CNC milling by Alejandro Romero

“The end result of this mission is a high-density foam mannequin showcasing completely different city densities of a hypothetical metropolis. The design course of utilises fabrication strategies akin to CNC milling to reimagine the digital mannequin by completely different CNC instruments and gear path densities.

“The mission is an try and merge city design with digital design and robotics fabrication.

“The mission intently examines city variables akin to city densities, circulation paths and volumes to redefine them as fabrication variables that may successfully contribute to the design evolution of city situations.

“Such an approach challenges the conventional urban design strategies while introducing digital fabrication as an urban design methodology rather than a final production tool.”

Student: Alejandro Romero

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

Future Materiality by Beken Amde and Tiarnan Mathers

“This construction explores the way forward for materiality by combining two supplies – the primary being mycelium as a biomaterial and the second being pure wooden materials.

“The wooden constructions, on this case, act because the formwork that hosts the mycelium mixture.

“The project explores a merge of digital fabrication methodology hybridisation, a high tech fourth axis milling technique with a low tech production of mycelium infused artefacts. It is made from milled wood blocks infused with mycelium.”

Students: Beken Amde and Tiarnan Mathers

Course: Fabrication and Robotics

Tutor: Fadhil Fadhil

Partnership content material

This faculty present is a partnership between Dezeen and New York Institute of Technology. Find out extra about Dezeen partnership content material here.

[adinserter block=”4″]

[ad_2]

Source link