[ad_1]

The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now.

3D printing materials and services provider CRP Technology has deployed its 3D printing capabilities and Windform SP carbon fiber material to create an innovative athletics track shoe.

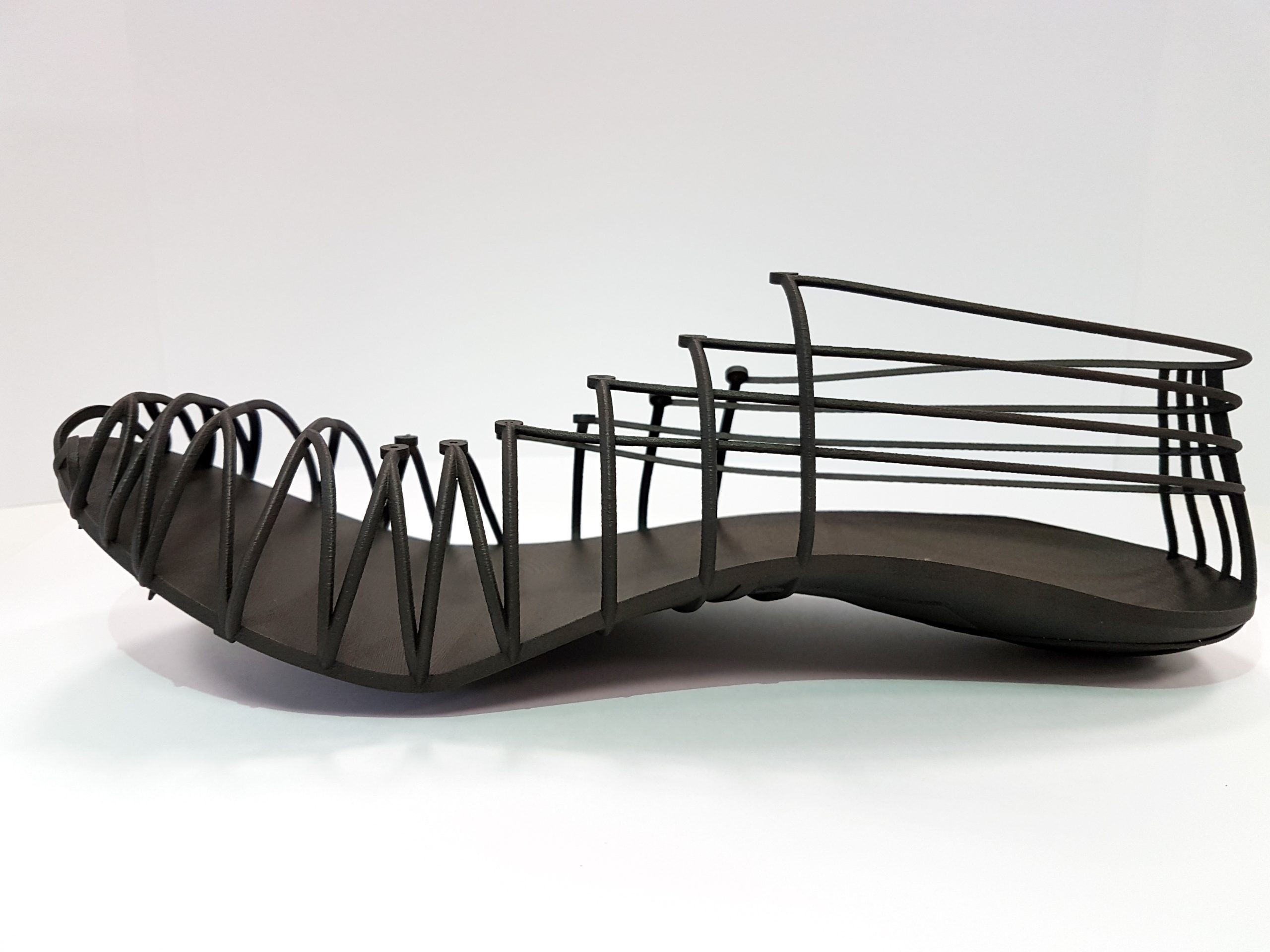

Working with Venetian middle-distance runner Miro Buroni, the company 3D printed the spike shoe, named Pleko, in a single piece using its powder bed fusion (PBF) laser sintering technology.

According to Buroni, the flexibility offered by 3D printing and the mechanical characteristics of CRP Technology’s Windform SP material enabled him to take his project to “the highest level” of customization and specialization.

Designing the Pleko spike shoe

Alongside CRP Technology, Buroni also enlisted the skills of Italian sportswear manufacturer Diadora to help design the spike shoe. They began by 3D scanning an athlete’s foot and conducting biomechanical analysis of their running and foot movement.

“With this mapping, we were able to model the shoe on the individual’s needs in terms of foot structure and athletic performance,” Buroni said. “Moreover, scanning and biomechanical analysis allowed us to understand the best placement of the traction system under the outsole – the ‘pins.’”

Once the design stage was complete, Buroni sought out CRP Technology to provide the 3D printing capabilities and materials to bring the project to fruition. The Pleko shoes required a material with “strong characteristics of resistance to bending” for the manufacture of the outsole, midsole, and ribbing structures, to ensure optimal force was transmitted to the shoes during racing.

“After a brief research, it immediately became clear that CRP Technology was the perfect company to realize my project, and that one of CRP Technology’s top composite materials, Windform SP, was the appropriate construction material,” said Buroni.

CRP’s Windform SP

Windform SP is a carbon fiber filled composite material in CRP Technology’s Windform TOP-LINE range of composites for PBF laser sintering. The company’s current Windform range includes its F1, XP, SP, FR, GT, LX, RL and FR2 composites, with its most recent addition being Windform RS, another carbon fiber filled composite material specially designed for PBF 3D printing.

CRP Technology developed its first Windform 3D printing material in 1996, which was later succeeded by Windform XT in 2005, the first carbon fiber-reinforced composite for SLS 3D printing. Since then, the Windform TOP-LINE composites range has been deployed for a wide array of highly demanding prototyping and end-use applications, such as cell pouch frames for batteries and pocket satellites and deployers.

Windform SP has been previously leveraged by safety specialist Joyson Safety Systems to 3D print a functional airbag housing container prototype. The material needed to maintain sufficient strength, impact resistance and heat stability in order to meet the stringent safety requirements of the part. Windform SP has also been deployed to 3D print a functional National Advisory Committee for Aeronautics (NACA) duct for its Streamliner vehicle.

The mechanical properties of Windform SP also appealed to Buroni during his search for a suitable material to create his Pleko spike shoes.

“Windform SP guarantees excellent resistance even in very thin thicknesses,” he said. “This feature allowed me to create spike shoes with a perfect foot envelopment, that facilitates an increase of the comfort and the enhancement of the performance.”

3D printing the Pleko spike shoes

CRP Technology was tasked with 3D printing not only the Pleko’s outsole, midsole, and pins, but also the shoe’s ‘ribs’, which originate from under the outsole and enclose the shoe where maximum effort is directed through the shoe during a race.

Responsible for carrying kinetic energy releases from an athlete’s biomechanical movement during a race, the rib structure is designed to embrace the athlete’s foot “like a cage” in order to facilitate improvements in their running technique. To achieve this effect, CRP Technology 3D printed the outsole, midsole, pins and ribs as a single unit in Windform SP.

“Thanks to the pins under the outsole, the cage in Windform SP allows the athlete to develop as much strength as possible, without losing energy,” said Buroni. “I positioned the deepest pins in the points of superior pressure of the feet against the ground. I also put smaller studs in other parts of the outsole: these studs are on an equal basis essential for the stability of the track shoes.”

The end result yielded a functional prototype that was resistant to deformation even at its thinnest thicknesses, while remaining flexible. The design was complemented by a sock-like upper that is almost completely detached from the structure and responsible for protecting the foot.

Once the structural part of the Pleko had been printed, Buroni carried out a number of tests on the spike shoe to evaluate its performance.

“The design and manufacturing technologies, combined with the Windform SP and its mechanical characteristics, made the Pleko track shoes highly innovative, taking the entire, whole project to the highest level of customization and specialization,” Buroni continued. “I am very satisfied with my 3D printed Pleko and Windform SP.”

3D printed footwear

The weight, design optimization and personalization benefits of additive manufacturing have seen it be increasingly leveraged for producing performance footwear in recent years.

German sportswear brand adidas has been at the forefront of this trend, having continually released new versions of its Futurecraft ‘STRUNG’ 3D printed sneaker and 4DFWD midsole, created in partnership with 3D printer manufacturer Carbon.

In July, cycle shoe producer Lore began taking preorders of its customizable 3D printed cycle shoe, the LoreOne, which was developed with more than a dozen patent-pending features.

Most recently, footwear 3D printing start-up Zellerfeld 3D printed a unique sneaker line, the ‘HERON01’, which it claims could potentially “reshape footwear for the better.” Featuring a scale-like design similar to that of a heron’s foot, the slip-on running shoe does not require stitches or adhesives and can therefore be fully recycled at the end of its life.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Miro Buroni’s Pleko spike shoes, 3D printed by CRP Technology. Photo via CRP Technology.

[ad_2]

Source link