[ad_1]

The BMW TwinPower Turbo technology is based on the twin-scroll principle and has been actively installed in BMW petrol and diesel engines since 2011.

The technology at a glance

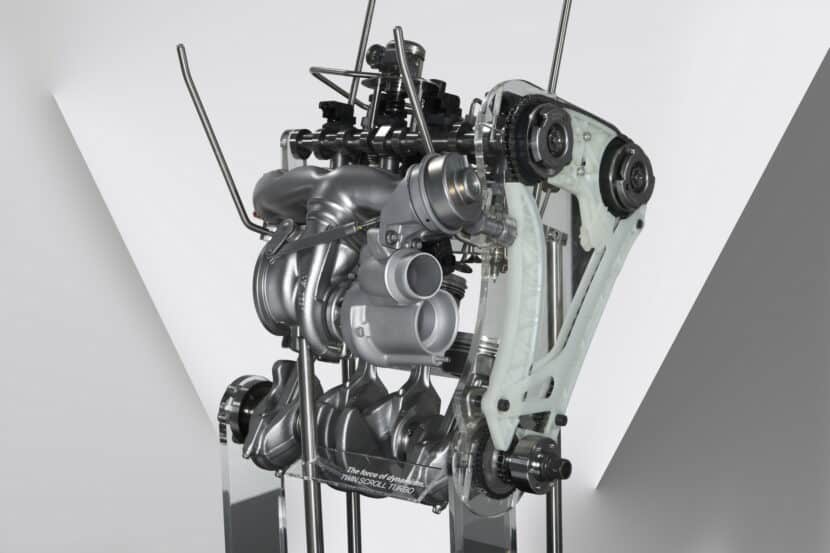

The innovative turbocharging technology also gave the greenlight for downsizing at BMW. Thanks to TwinPower Turbo, some of the preceding 6-cylinder engines in the lineup have been replaced with 4-cylinder units that were superior in terms of efficiency, response and pulling power.

The BMW TwinPower Turbo has many benefits, as it allows for more variability within the engine range and also helps improve fuel consumption, whilst also reducing the CO2 emissions thanks to the enhanced, effective gas recirculation process.

Of course, as to achieve maximum productivity, TwinPower Turbo works in conjunction with the High Precision Injection, the Double VANOS variable camshaft control and VALVETRONIC variable valve control.

The very first application of BMW TwinPower Turbo came in 2011, when the constructor launched the new BMW X1 xDrive28i variant, that used a newly developed 4-cylinder petrol engine replacing the old 3.0-liter, straight-six, naturally aspirated powerplant.

The preceding 6-cylinder N52B30 unit, that previously powered the X1 xDrive28i (2009 – 2010) and delivered 180 kW / 245 PS (241 hp), was sent into pasture by the state-of-the-art, turbocharged N20B20 unit with I4 architecture and rated at the same maximum output of 180 kW / 245 PS (241 hp).

The new N20 powerplant developed a peak output of 350 Nm, available as early as 1,250 rpm. At the same time, the 0-100 km/h acceleration was improved by up to 0.3 seconds compared to the preceding version, reaching 6.5 seconds. Furthermore, thanks to the BMW EfficientDynamics measures and the TwinPower Turbo technology, the average fuel consumption dropped by 1.5 liters to 7.9 l/100 km, compared to the naturally-aspirated I6 engine.

Alongside the new 4-cylinder petrol engine, BMW also premiered a 6-cylinder diesel engine complete with TwinPower Turbo in 2011. The new 3.0-liter I6 diesel powerplant, titled N57D30O1, came up with an increased output (190 kW / 258 PS) and boasted further optimization in the areas of reduced internal frictions, weight and fuel injection.

The updated N57 powerplant featured a high-precision, Common Rail diesel injection at a pressure of 1,800 bar. The gain in torque was of 20 Nm to 560 Nm over the preceding engine, already available from 1,500 rpm.

Furthermore, the turbocharger was equipped with variable intake geometry, alongside a reduction in the turbine wheel. In the F10 530d xDrive, the acceleration from 0-100 km/h took just 6.1 seconds, whereas the average fuel consumption to 5.7 l/100 km.

BMW TwinPower Turbo: It’s all in the name

As evoked in the first paragraph, BMW developed its trailblazing TwinPower Turbo technology on the basis of the twin-scroll principle. So, basically, the name says it all, but although intuitive, it’s not that straight-forward to many.

First of all, one of the common mistakes is that many believe twin turbo equals biturbo, which is false in most cases, even though both rely on two turbochargers. Another misbelief is that TwinPower Turbo actually denotes a twin turbo configuration, which really is not the case.

So, to clarify, let’s start from the following definitions:

- twin turbo technology employs two turbochargers that are placed one next to the other (“twin”)

- biturbo employs 2 turbochargers as well, yet they are located one on each side of the cylinder bank (typical for V8 engines)

- BMW TwinPower Turbo is relying on a single turbocharger with two scrolls

- BMW TwinTurbo Power (yes, this one exists too) relies on two turbochargers

- TwinPower Turbo is not the same as TwinTurbo Power, so don’t mix them up

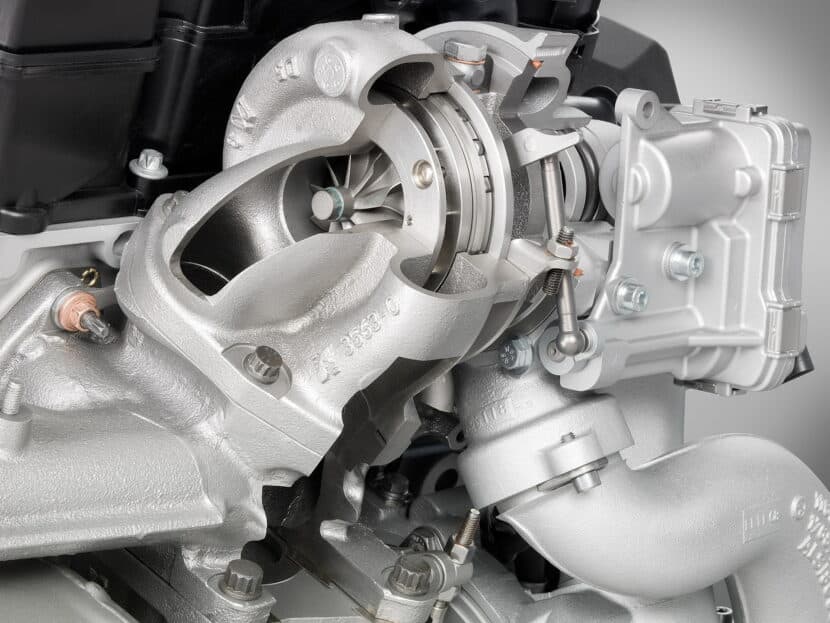

Sounds easy, huh? It partly is. The TwinPower Turbo technology from BMW involves what’s called a divided inlet turbine and a properly-designed exhaust manifold. The latter component is of crucial important, because it helps pair the cylinders correctly as to properly direct the flow of exhaust gas independently on one scroll.

As you may recall, the TwinPower Turbo is currently fitted to either 4-cylinder and 6-cylinder BMW engines, irrespective of the running fuel (diesel or petrol). In inline0four applications, cylinders that fire 1st and 3rd are teamed up on one scroll, whereas, cylinders that fire 2nd and 4th in the sequence are paired on the second scroll.

In case of the inline-six powerplants, the combination order is typically 1-3-5 on one scroll, 2-4-6 on the other scroll. In what BMW V8 units are concerned (the N63/S63 generation), the need for more power led to the adoption of twin turbo, so 2 turbochargers placed together, given the hot inner V architecture (with the turbochargers placed between the cylinder banks). And yes, the turbocharging technology in the 8-cylinder powerplant is called BMW TwinTurbo Power, although not visibly labeled.

Moving on to TwinPower Turbo which relies on the twin-scroll principle, compared to single-scroll turbochargers, the benefits are substantial in the following respects:

- a proper and quicker boost response, given the balanced pairing of cylinders based on firing order

- sustained, uninterrupted power delivery at all engine speed, based on constant recirculation of exhaust gases through the twin-scroll

- maximized pulse energy feeding the turbocharger wheel

- increase of running efficiency and life of the turbocharging unit

- significant reduction in turbo lag and fuel consumption

- improved low-end power delivery, similar to twin turbo engines

- notable improvement in reducing pumping losses

To maximize the benefits of BMW TwinPower Turbo, several other components have been developed as to increase the balance and smoothness in the engine functioning. The vertically offset balancing shafts optimally compensate the vibration, whereas the centrifugal force pendulum integrated in the dual-mass flywheel acts to prevent any irregular engine rotations that are prone to appear at low rpm.

[ad_2]

Source link