[ad_1]

With the University of Edinburgh’s FloWave facility well established as a leading testing site for tidal and wave energy innovations, its recent adoption of Fastblade’s new hydraulic technology is set to secure Scotland’s reputation for making major advances in the marine renewables sector. By Colin Cardwell

When energy companies recently approached the government for help in coping with the enormous hikes in the price of natural gas – which comprises 40 per cent of the UK’s energy mix – it was a salutary reminder to corporates and their customers that green energy wasn’t just a reassuring parallel development that would helpfully kick in some day.

It was something that we needed to address with renewed urgency.

There are several solutions: solar energy, while increasingly popular is intermittent (especially in Scotland) which can cause disruptions to grid operations while below-average wind speeds over the past year is a reminder of the risks of a strategy that over-commits to wind power.

However, while the moon remains in orbit and oceans cover 71 per cent of the earth’s surface, tidal and wave energy is both powerful and predictable.

Harnessing its potential is at a relatively early stage but at the forefront of the sector is the University of Edinburgh’s FloWave Ocean Energy Research Facility which is designed both to allow academic research into wave and tidal current interactions and help companies developing marine energy generation devices to test their ideas before deploying them in the sea.

FloWave has operated since 2014 as a fully integrated part of the University of Edinburgh helping to ensure Scotland’s continuation as a global centre of excellence in ocean energy technology.

At the facility, the world’s first circular combined wave and current test basin, a 25-metre diameter tank recreates complex waves and fast ocean currents focusing on R&D and the testing of clean energy technologies, acting as an ocean simulator.

Now the School of Engineering is set to commission FastBlade by the end of this year as another world first – a test facility that uses regenerative hydraulic technology to offer high-quality, low-cost fatigue testing of tidal blades and other composite structures for research and product development.

The University of Edinburgh FastBlade team recently met with Fife College to prepare the digital skills training center that will be part of a new training suite. Pictured left to right, Fife College’s Dougie Knox and the University of Edinburgh’s Peter Williams, Fergus Cuthill and Sergio Lopez Dubon. Photograph: Jeff Steynor

It will, says Dr Tom Davey, test facility manager at FloWave, help to secure Scotland’s lead in marine energy as the world’s first dedicated fatigue test facility for tidal blades.

The unique tidal blade designs are three to four times the cost of wind blades despite being roughly one-tenth of the length and FastBlade will reduce the technical and commercial risk associated with these components.

Dr Jeffrey Steynor, project engineer at FloWave until 2017 has led the development of the FastBlade facility design and development since then.

“FloWave tests scale models in the programmable and controllable test basin environment, while FastBlade tests full scale components including tidal blades and other large composite structures,” he explains.

Dr Davey continues: “The facilities work in partnership, taking things from concept stage at FloWave then passing it on to FastBlade before it goes into the sea, feeding knowledge and expertise back to the university’s doctoral training centres to inform the training of the next generation of people working in the sector.” While they are doing fundamentally different things, he says, one facility feeds important data into the other.

“At FloWave we can learn about the sort of the overall architecture of the concept and conduct tests at reasonable costs – so if something doesn’t work you haven’t taken a significant financial risk and can refine the design.”

The academic-industrial link is strengthened by the involvement of PhD students who help companies understand the data and make sense of the small-scale tank tests at FloWave.

Some 20 undergraduate students have been working on projects at FastBlade and, says Dr Steynor, the facilities are used to train and upskill engineers, allowing them to apply what they have learned in university to real-world situations. “FastBlade is testing the actual forces on the tidal blades so you may learn through a combination of tank testing, field measurement and numerical modelling what your expected loads are going to be on the blade,” he says.

“These technologies go through several development processes from a concept drawn on the back of an envelope, graduating to tests, then more advanced tests with more realistic conditions, sensors and data.

“We take a full-size blade from a system, which is as big and strong as it will ever be in the ocean, test that with ocean-sized forces in a very direct manner which allows us to say, for example, that it will last 20 years in the ocean.”

Work began at the £4.4 million FastBlade facility at Rosyth last June, built by the engineering giant Babcock International, through a relationship supported by Edinburgh Innovations, the University’s commercialisation service. It has been funded by the Engineering and Physical Sciences Research Council (EPSRC) and the University of Edinburgh. “That investment means that Scotland will now have two of the world’s first facilities to support renewable energy facilities to go from conception to reality,” says

Dr Steynor.

“With these really high fidelity, complex labs the industry can figure out potential problems in advance and significantly de-risk the process.” Which is important: testing at full scale means that they can avoid making expensive mistakes in the ocean that they could have anticipated in our laboratory, he adds. With the cost of tests at FloWave then FastBlade ranging from US$10,000-300,000 and the cost of deploying the technology in the ocean $3-10 million, it makes sense to have as many risks as possible mitigated in the lab than making very expensive mistakes at a later stage, he says.

Drs Davey and Steynor are both members of the International Electrotechnical Commission (IEC) whose first president was Lord Kelvin, Professor of Natural Philosophy at the University of Glasgow and the IECRE (the body’s renewable energy arm).

“Tom and I work closely with the IECRE, with the tidal sector and the wave energy sector on a development path so that we can bring marine renewable on stream commercially and viably,” says Dr Steynor.

Dr Davey adds: “I think it’s important to note that this represents a real link between academia and industry. Companies for example may be working with industrial doctoral centres with a student embedded; the university is able to interface with them at all stages from those who are at quite a conceptual stage all the way up to companies like Orbital Marine Power which is at a very different stage of maturity who all benefit.”

Those more mature companies might well revisit FloWave as they progress to the next generation of devices, giving them a new avenue to do that broad scale testing, he says. While for start-ups FloWave is a member of MaRINET2, the Marine Renewables Infrastructure Network composed of 39 organisations who collaborate to progress offshore renewable energy technologies in Europe and which has already awarded €4.8 million in testing access, delivering more than 400 weeks of free testing at its network of facilities.

The facilities work in cooperation with several institutes and companies, including doctoral students and research groups at the University of Oxford. And as the global climate conference approaches, FastBlade has been selected to be on the COP26 Universities Network Innovation Showcase website.

“COP26 is a great opportunity to showcase what we have to offer,” says Dr Steynor.

“This is a world-first facility – just as FloWave was – and people will travel here to use these facilities and return due to positive results.”

The opportunities are readily apparent. “You could come from Korea to Scotland, do your testing here, take those results back to Korea get insurance from Zurich – and then deploy in Canada. Because the IECRE is an internationally recognised stage-gate process it would all be certified and verified through them and it’s important that the university is aligned with that,” he says.

———————————————

Global recognition for Orbital Marine

ORBITAL Marine Power (Orbital) was recently chosen as one of only 12 companies invited to take part in the Global Investment Summit (GIS) which took place last week in London and was hosted by the Prime Minister and supported by members of the Royal Family.

The Summit programme and sessions aimed to showcase the most innovative green technologies and companies already operating in the UK and highlighted the UK’s leading global position and commitment to Net Zero.

Working towards delivery of the Prime Minister’s Ten Point Plan for a Green Industrial Revolution, the Summit brought 200 of the world’s most prominent decision makers, C-Suite executives, and investors to the UK.

Minister for Investment Gerry Grimstone said: “Our industries of the future like tidal will not only help ensure a cleaner, greener planet but also create high value jobs in Scotland and across the UK.”

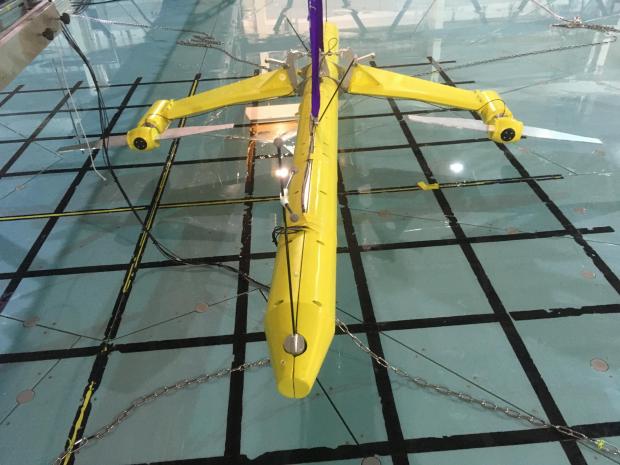

Orbital Marine has had a long-standing client relationship at FloWave Ocean Energy Research Facility and earlier this year conducted a testing campaign there on a scale model of its O2 tidal turbine, which has now been launched from the Port of Dundee.

The unit is now installed in the waters off the Orkney Islands in northern Scotland where it is feeding power into the UK grid.

Supported by the INTERREG France (Channel) England TIGER project, Orbital’s hydrodynamics team tested 1:20 scale models in a programmable and controllable test basin environment at FloWave and trialled different low-cost mooring configurations for a wide range of sites.

The team gathered data at FloWave to inform the development of more powerful powertrains and rotor sizes for the company’s O2 tidal technology, while ensuring platform stability across the worst combinations of wave and current scenarios, including 100-year storms conditions.

This was made possible by a circular array of 168 wave makers around the edge of the tank and 28 impellers under the surface simulating tidal currents flowing from any direction, simultaneously with sea conditions containing a huge range of waves.

Dr Tom Davey said that FloWave has been heavily involved with the Wave Energy Scotland (WES) programme and has seen that increasingly progress into technologies that are going into the sea. “We’re busier than ever with wave energy projects and the technology is proving healthy. On the tidal energy side, we are still involved in more academically-led projects which have also maintained a high tempo.”

[ad_2]

Source link