[ad_1]

In a major stride in direction of decarbonising transportation with hydrogen, Daimler Truck and Linde Engineering, two industrial giants, have achieved a groundbreaking infrastructure breakthrough. Their collaborative efforts have led to the event of sLH2, a novel course of for dealing with subcooled liquid hydrogen, providing a variety of benefits over conventional gaseous hydrogen strategies.

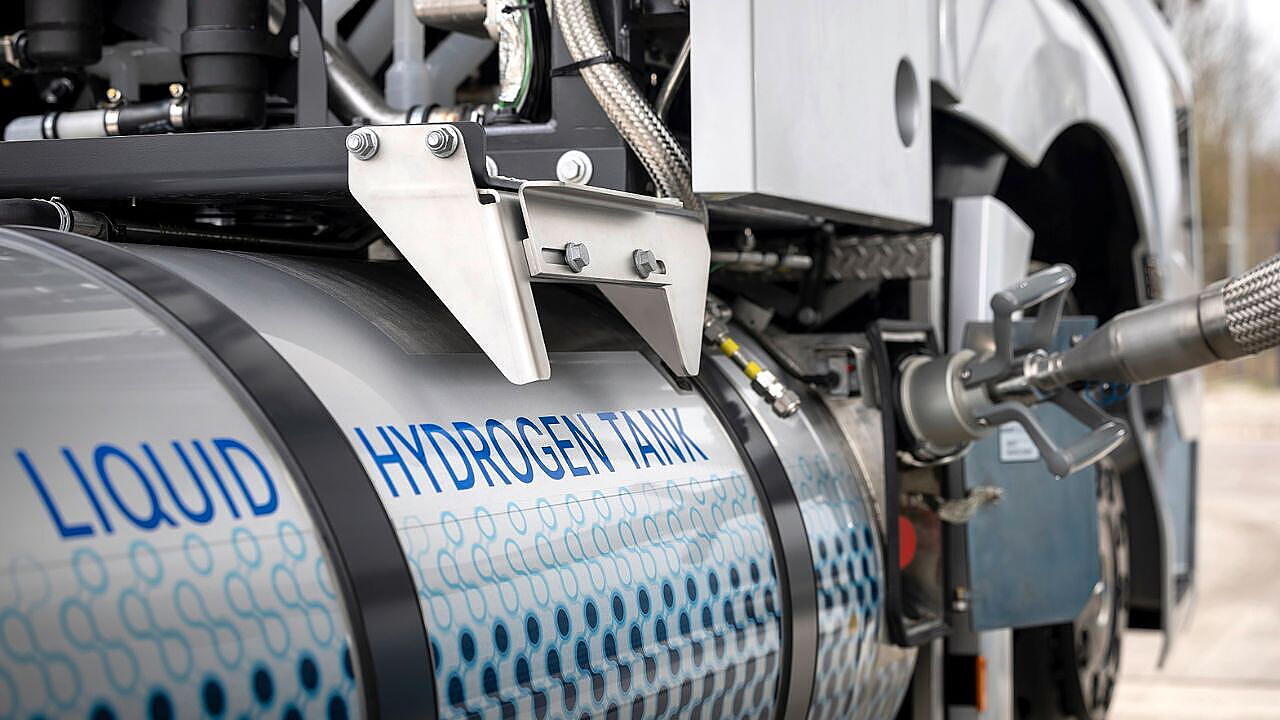

Engineers from each firms have labored collaboratively on sLH2, which boasts greater storage density, prolonged vary, quicker refuelling, decreased prices, and improved power effectivity in comparison with gaseous hydrogen. The progressive method allows heavy-duty vans to be refuelled in simply ten to fifteen minutes, carrying 80 kg of liquid hydrogen for a variety exceeding 1,000 kilometres. This know-how not solely enhances effectivity but additionally considerably reduces the funding required for hydrogen refuelling stations and operational prices.

The sLH2 course of, in comparison with standard liquid hydrogen (LH2) refuelling, utilises an progressive pump to barely improve the stress of the liquid hydrogen, remodeling it into subcooled liquid hydrogen. This methodology simplifies the fuelling course of, minimises power losses, and eliminates the necessity for knowledge transmission between the refuelling station and the automobile.

The inaugural public sLH2 pilot station in Wörth am Rhein, Germany, marks a milestone in power effectivity and efficiency. With a considerably low power consumption of 0.05 KWh/kg, the station requires 30 occasions much less power than standard gaseous hydrogen refuelling. Its small footprint and excessive capability make it a sensible and cost-effective different for heavy-duty automobiles.

Daimler Truck and Linde Engineering are working in direction of establishing sLH2 because the main hydrogen refuelling know-how for heavy-duty vans. The know-how, out there by an ISO customary, promotes transparency and openness, urging different stakeholders to undertake the usual and contribute to the worldwide mass marketplace for the method.

Andreas Gorbach, Member of the Board of Management of Daimler Truck, emphasises the significance of three elements for zero-emission transport: applicable automobiles, an intensive infrastructure community, and price parity with diesel vans. He calls on different trade gamers to undertake sLH2 know-how as an trade customary.

Juergen Nowicki, CEO of Linde Engineering, highlights the practicality and environmental advantages of sLH2, presenting it as a CO2-neutral different to diesel within the heavy-duty automobile sector. The decreased funding and operational prices are anticipated to result in decrease whole possession prices.

The sLH2 know-how is about to be applied within the Mercedes-Benz GenH2 Truck customer-trial fleet from mid-2024 onwards, showcasing its real-world functions in CO2-free long-distance transport. As these trials unfold, Daimler Truck and Linde Engineering intention to show the viability of hydrogen-powered vans and the urgent want for a widespread worldwide refuelling infrastructure and a sustainable provide of inexperienced liquid hydrogen.

Also Read:

GM, Honda Unveil Hydrogen Fuel Cell Production At JV Facility

[adinserter block=”4″]

[ad_2]

Source link