[ad_1]

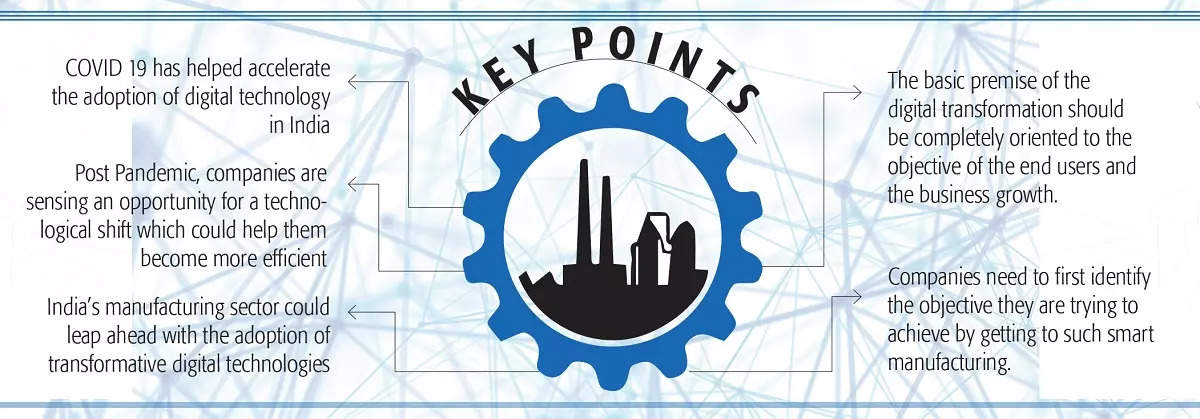

The workforce is rapidly changing, as the Indian economy is recovering after the several challenges over the last 18 months. Companies are sensing an opportunity for a technological shift which could help them become more efficient, as they move to one or more technologies.

India’s manufacturing sector could leap ahead with the adoption of such transformative technologies. This was the topic of the virtual discussion at The Economic Times- Dell Technologies titled- ‘India Manufacturing Tech Transformed’.

Need to scale up manufacturing

“The need of the hour is to go up in the manufacturing value chain. If India is to become a $5trillion economy, the manufacturing sector has a very important role to play. Manufacturing now contributes to around 16-17 percent of the GDP, that would have to go up significantly to around 24-25 percent as we move to a larger economy,” he said.

He explained that there were huge job opportunities that were created when the country started embracing computers and the information technology revolution started in India.

“People used to wonder if they would lose their jobs, if the companies adopted technology. But look what happened, there were enormous number of job opportunities created. Big IT giants like TCS, Infosys, Wipro took birth from that revolution,” he pointed out.

Helping achieve business goals

“The pandemic put a lot of restriction on the travel time and meeting people, but the show must go on. We can’t stop the manufacturing and so we adopted a lot of technology which enable us to do remote monitoring and inspection,” he said.

Patil stated that their company managed to install a big nuclear project in France through remote monitoring, it was totally on smart glasses and other technologies. “And we could install the entire nuclear plant in three months remotely. We didn’t travel to France at all. It is an example of how we could remote install and commission such a huge plant by just using technology,” he explained.

Ajeya Motaganahalli, CTO SPS Business Group, Honeywell Technology Solutions informed that this is the decade for autonomous operations.

“During the pandemic there was tremendous pressure on the warehouses, as the buying patterns of the people had changed for good. So, with the help of digital and smart technologies, warehouses were able to manage the single day delivery not just in India but anywhere in the world,” he said.

Should be objective oriented

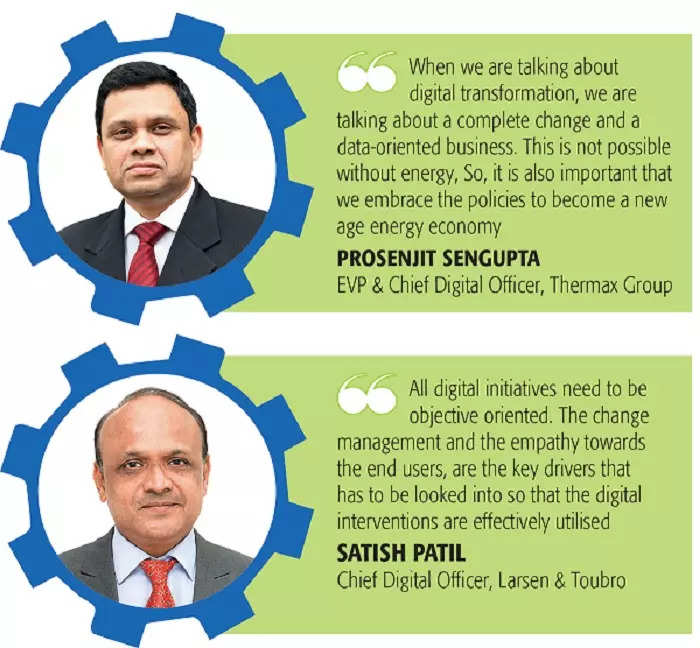

Prosenjit Sengupta, EVP & Chief Digital Officer, Thermax Group informed that until and unless these objectives are very focussed in nature, the company can at best achieve automation in bits and parts.

“One thing that the digital transformation is teaching us is that we cannot achieve transformation until and unless we are bringing multiple view-points and areas together,” he added.

Adding to the narrative, Rajeev Singh stated that companies need to first identify the objective they are trying to achieve by getting to such smart manufacturing.

“A lot of companies try to get into finding solutions even without first understanding what they are trying to achieve. There should be a common rallying objective through which they can put together all the stakeholders to understand what they wish to achieve. It can be as simple as reducing the manufacturing cost or to reduce the downtime,” he pointed out.

Need to constantly reinvent

Speaking about the challenges faced by the Indian automobile sector, S Devarajan, Senior Vice President- Production, TVS Motor Company informed that the sector needs to constantly reinvent itself to meet the changing demands of the customer.

“India is among the top in the automobile manufacturing in the world. There are still challenges on how we can be more competitive. In the last few years, we are trying to interconnect and become a lot more transparent,” he pointed out.

He explained that over the years many players in the automation industry have tied up and have made into an improvement of the automation because of the labour requirements.

“But the major thing is that last few years, we are trying to interconnect all these things and become more transparent. In TVS we have taken, IT and IoT end to end. From the dealer to the customers, to the factory, to the supplier and the community. The opportunity is huge for all of us,” Devarajan added.

Technology, a multiplier for the companies

Vivekanand Manjeri, Brand Director, Client Solutions Group, Dell Technologies, India stated that today digital technology is there on every company’s agenda.

“In the last 18 months, most companies had no option but to embrace a faster pace of transformation because of what the external environment brought about in the businesses. We believe that there would be some key technology trends that would be enablers to the transformation,” he explained.

Leverage on digital technology

The manufacturing sector given the constraints due to the pandemic would always have some limited resources, the need of the hour would be to leverage on the digital technology.

Satish Patil, Chief Digital Officer, Larsen & Toubro stated that the machines can be made intelligent enough so that the productivity output can be measured. “There would always be limited resources in terms of space, manpower or other resources. To only way to cater to achieve your business goals is logging a non- liner way where the adoption of the digital technology takes the cake. We took care of the machines and made it more and more automated,” he said.

Giving the example of L& T, Patil mentioned that their company has adopted technologies like artificial intelligence to monitor wielding work at their engineering projects.

“If you start looking at the defects on the wielding manually it is time consuming so we use artificial intelligence where we pass on the Radio glass or the photo images of the particular valve section and it automatically detects the cracks or the seam patterns etc and gives a heads up to the workers,” he said adding that through this way the workers will focus only on those aspects and then try to improve the productivity.

Need to effectively harness data

India had just about 18 million phones, in the year 1997, which has grown to around a billion phones today. The country can build on that kind of experience to do something similar for manufacturing.

“The amount of data that was created world over till today will be amount of data that will be created in the next five years,” Ajeya Motaganahalli said.

Lot of data that we are seeing getting generated, needs to be harnessed through the right adoption of technology to unlock the power of data.

“You also need to add value across the entire value chain. Are you able to generate insights in real-time by connecting different machines and the technology by generating this data?” Vivekanand Manjeri informed.

He informed that a lot of times, you generate insights not just through one data point, but by looking at large amounts of data points coming in real-time to make quick decisions because the speed of decision making would be critical.

“One of the important things that you see in manufacturing across the world is mass production vs hyper-personalisation. Once a customer decides that he wants a particular type of colour in a shoe, you need to quickly translate that to the shop owner. It might have worked in B2C earlier, but today even a lot of B2B customers are demanding that,” he added.

[ad_2]

Source link