[ad_1]

The Smithfield Foods plant in Sioux Falls, South Dakota

Photographer: Dan Brouillette/Bloomberg

Photographer: Dan Brouillette/Bloomberg

Smithfield Foods Inc. thought it was doing great. In the first quarter of this year, the pork giant’s earnings were up 190% over the same period in 2019. Then the pandemic hit, and the close quarters of meatpacking plants made them ideal places for the coronavirus to spread.

Employee infection rates spiked, forcing temporary closures and sudden shortages in supermarket meat aisles. After its revenue plummeted in the second quarter, Smithfield and other meat processors started looking around for strategies to make sure the same thing didn’t happen again.

While the industry has in some cases installed plastic shields between workstations and made other coronavirus-related changes, some executives contend social distancing isn’t feasible in such a labor-intensive environment. Smithfield, the largest pork company in the world with 42,000 employees in 40 U.S. locations, decided to invest in some relatively new technology to deal with the threat of contagion.

Howard Anderson, the company’s chief engineer, said he reviewed a range of novel approaches, but was most hopeful when it comes to ionized hydrogen peroxide vapor—and a machine built by San Diego-based Puradigm and distributed by Dayton, Ohio-based Extreme Microbial Technologies (EMT).

“What we liked about [the technology] is that it’s a proactive solution,” said Anderson. Many other options are passive, requiring that air be pulled through a unit to be treated. Smithfield, owned by Hong Kong-based WH Group, said it has installed the units in six locations, including a plant in Elizabeth, New Jersey, and Sioux Falls, South Dakota, with three more locations soon to follow.

A Puradigm manufactured unit

Source: Extreme Microbial Technologies

According to data collected by Food & Environment Reporting Network (FERN), some 42,567 meatpacking workers have tested positive for Covid-19 and 203 have died

In the spring, the Smithfield plant in Sioux Falls became the number one virus hotspot in America, with a cluster of 644 confirmed cases among employees and people they were in contact with. In May, 76 workers at the largest of the Smithfield Foods plants in Tar Heel, North Carolina, became infected, according to local health officials.

The U.S. Occupational Safety and Health Administration, the federal agency responsible for the safety of workers, recently fined Smithfield $13,494. The company is fighting the penalty. Smithfield declined to comment on how many of its employees have been infected or died in the pandemic.

Read More: Smithfield Fine in Deadly Covid Outbreak Labeled ‘Paltry’

EMT, which was started in 2016, contends the Puradigm technology it distributes is an environmentally safe way to help reduce coronavirus in the workplace. But experts say it’s a long way from being able to clear pathogens from the air.

The backbone of the technology is a “coated honeycomb matrix” that, when hit by ultraviolet light, pulls moisture from the air and forms hydrogen peroxide. Particles are pushed out of the machine, spreading through a room and landing on surfaces. According to EMT, when the particles come into contact with pathogens, a chemical reaction neutralizes them.

The company distributes standalone units for office spaces (which are the size of a waste-paper basket) or tech that uses a building’s heating and cooling (HVAC) system for bigger areas.

According to the Trump administration, hydrogen peroxide is active against a wide range of microorganisms, including bacteria, yeasts, fungi, viruses and spores. But at high concentrations, the molecule can be harmful to humans. EMT contends the limited amount of vapor produced by the machines makes them safe for humans as well as food production.

In a study done for Puradigm by the University of Florida in August, the company’s technology was found to be 99.7% successful at reducing microbial contamination levels of the coronavirus on stainless steel surfaces. But this is only a first step toward total indoor protection, since most coronavirus transmission is believed to take place through airborne droplets.

“Surfaces are responsible for maybe 5% of all transmissions. Likely much lower,” said Dr. Erin Bromage, an associate professor at University of Massachusetts, Dartmouth, and an infectious disease expert. “This technology would not work fast enough, nor penetrate a droplet traveling through the air in time to inactivate it before hitting a person’s face.”

Still, Puradigm’s devices have been shown to work against a long list of contaminants that food companies were already worried about, including E. coli, Salmonella, Listeria and the norovirus.

Dr. David Acheson, a food safety expert and former official with the U.S. Food and Drug Administration, said that if a vapor mechanism can kill the norovirus, it can kill the coronavirus. The FDA granted an Emergency Use Authorization for vaporized hydrogen peroxide to decontaminate N95 respirators, a process used by 6,300 hospitals across the U.S.

“It’s a reasonable assumption that it will work on surfaces,” Acheson said. “But any evidence that it will prevent person-to-person transmission [is] a big question mark,”

Despite the questions, industry analysts are cautiously optimistic about the technology.

“Let’s say we get a vaccine tomorrow that everyone wants to take, I think that as these investments move forward, it’s about future proofing [a building],” said John Walsh, an industry analyst at Credit Suisse. “It’s a way that buildings are going to help distinguish themselves to get people back into [office] spaces.”

But for Nick Santhanam, a senior partner at McKinsey & Co., whether companies like Puradigm and EMT keep growing after the Covid-19 pandemic recedes remains an “open question.”

“People are thinking about it, and clients are asking about it. You’re going to see a massive surge [in adoptions],” Santhanam said. “But will it keep going? That’s tbd.”

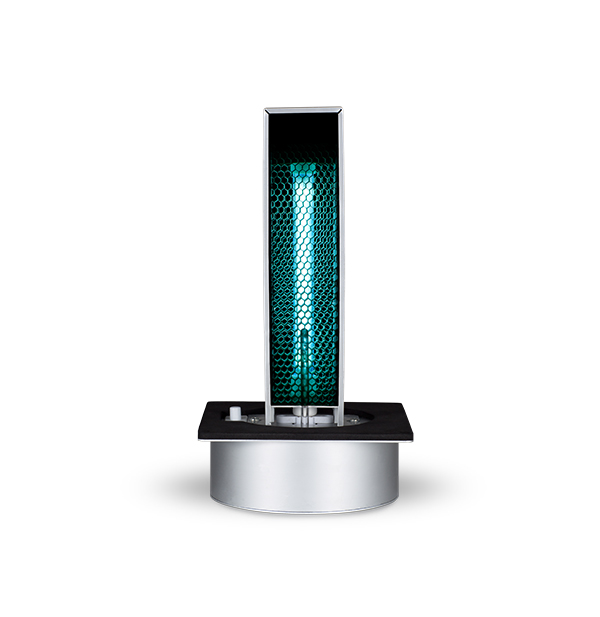

Puradigm’s Zone unit

Source: Puradigm

Randy Mount, 51, chief executive of EMT, began his career in real estate remediation, eradicating contaminants like mold from residential homes. That was how he stumbled upon the use of vaporized hydrogen peroxide. “We could decontaminate anything,” said Mount. “Restaurants, homes, universities and schools—we started getting a reputation for being the guys to call.”

In addition to Smithfield, his distribution list now includes French-owned Bonduelle Fresh Americas, which he said installed units in one of its four U.S. locations; sausage maker Glier’s Goetta, which has six units in its Covington, Kentucky, production facility; and Graeter’s Ice Cream, a 1,500 employee-company that has installed seven machines in its production facility in Mt. Auburn, Ohio.

Installation costs are calculated by cubic feet and bio-load (the number or range of microorganisms in a facility). A machine for a typical food production facility of 5,000 square feet with 12-foot ceilings would cost about $11,000. Mount said his company is on track to make $10 million in sales this year.

Vapor purification, or “nonthermal plasma,” was patented in 2014 by Puradigm. While some businesses began taking steps to address airborne threats long ago, most didn’t see the benefit, given the expense. The pandemic has changed that, creating a huge opportunity for businesses already in the field as more food-processing and food retail look for help.

Padraig Lawlor, Puradigm’s chief operating officer, estimated his company’s 2020 sales will be $17 million, which includes resellers, distributors like EMT and its own sales. But next year, his projection is $72 million. Lawlor said the company is mulling an IPO for 2022.

Customers place orders inside a Chipotle in Culver City, California.

Photographer: Patrick T. Fallon/Bloomberg

One retailer that put such precautions in place was Chipotle Mexican Grill, a restaurant chain which grappled with norovirus outbreaks in 2015 and 2017.

In between those years, the company installed combination ultraviolet/vapor hydrogen peroxide systems built by RGF Environmental Group Inc. In 2018, Chipotle added separate restroom units to “address microbiological contaminants, including viruses that originate there,” wrote Kerry Bridges, Chipotle’s vice president of food safety, in an email.

The air-purification systems sold by RGF are similar to what Puradigm makes, said Dr. James Marsden, RGF’s executive director of science and technology. Marsden was a professor at Kansas State University and led Chipotle’s food safety group after the norovirus outbreak.

RGF’s Reme Halo ionizer unit.

Source: Ryan Murphy/RGF

Florida-based RGF said its sales grew by 500% this year, and that it’s currently testing its product’s effectiveness against the coronavirus.

At Chef’s Garden’s, a 350-acre vegetable farm in Huron, Ohio, that sells to high-end restaurants, business vanished when Covid-19 arrived. As the company pivoted to direct-to-consumer sales, Chief Executive Officer Bob Jones, Jr. looked for ways to protect his 140 employees. He installed units distributed by EMT in April, both to keep staff healthy and “protect the integrity of the product,” he said.

Mike Willing, chief executive officer of Aloha Seafood in San Francisco, said his company’s biggest problem before the coronavirus was that when someone got the flu, it would spread like wildfire through the staff. In 2019, he installed machines obtained from EMT. Since then, Willing said he hasn’t had a single case of the coronavirus to report. “We feel more comfortable with it and my guys are ecstatic,” he said.

(Corrects to clarify that EMT distributed products manufactured by and containing technology patented by Puradigm. )

[ad_2]

Source link