[ad_1]

The previous 25 years marked the emergence of shale as the subsequent frontier for oil and fuel manufacturing, and JPT’s Houston workplace was proper in the midst of all of it.

Credit for beginning this disruptive change goes to George P. Mitchell who led a 17-year-long effort to extract fuel from the ultratight rock within the Barnett formation. A JPT story described how this effort was finally looking like a significant, profitable business in 1998 when Mitchell Energy’s engineers turned to lower-cost slickwater fracturing in their vertical wells.

The success of this trial-and-error engineering marathon drew little discover on the time. But that seed grew into an enormous enterprise primarily based on expertise that confirmed it was attainable to profitably produce oil and fuel from just about impermeable rock utilizing large-scale fracturing and ever-longer horizontal wells.

In the approaching many years this reverberated by drilling, fracturing, and reservoir engineering, disciplines whose physics-based view of the world couldn’t predict how that may occur.

As JPT’s workers grew with the addition of reporters protecting rising expertise, there was no ignoring what was occurring round us.

The journal highlighted futuristic reservoir monitoring concepts in Saudi Arabia and advances in deepwater expertise in Brazil, however the booms and busts of this high-profile enterprise that delivered extra oil than income saved altering in fascinating methods.

The first SPE Hydraulic Fracturing Technology Conference I coated in 2011 was wonderful and puzzling to this expertise novice. I questioned how they may create fractured areas that appeared like shoe packing containers.

At an early present, a speaker suggested those that believed that fracturing information started with shale to look again additional in OnePetro.

One of these paper authors, then and now, is Dave Cramer, senior engineering fellow for ConocoPhillips, who started studying fracturing when he graduated from school with a enterprise administration diploma and obtained a job with Western Company of North America.

The singular change over the previous 25 years is how a lot fracturing has been scaled up. “It like a factory out there, and it was not a factory when we started,” he stated.

In the earlier 25 years, fracturing specialists had been doing numerous progressive issues. He proudly remembers being concerned in a job for Amoco the place they pumped 600,000 gallons of gelled fluids and 1.3 million kilos of large-mesh sand right into a 35-ft tight sandstone part of a properly within the DJ Basin in Colorado.

The morning he advised that story he was evaluating a properly accomplished in Canada the place ConocoPhillips used slickwater to pump 970,000 kilos of sand per frac stage.

In some methods the job in 1978 looms bigger in his thoughts. The entire job was geared toward a single goal and was refined: They pumped 5 totally different fluid mixtures because the job progressed primarily based on their lab testing and fracture modeling.

While he thinks the technical expertise of these fracturing tight rock again then are underestimated, wells now with laterals which can be miles lengthy and tons of of clusters to stimulate are a lot extra complicated, which has created an insatiable urge for food for information by engineers frequently feeling strain for higher manufacturing and effectivity.

“Diagnostics are a lot better. Back then the only thing available was treating pressure analysis,” he stated. Now along with that there are a number of measures from fiber-optic cables, downhole photos of perforations, microseismic, and a number of take a look at websites evaluating the professionals and cons of every of those diagnostic components.

To sustain with the size and tempo of the roles, the {hardware} and strategies used to ship the provides and do the fracturing have quickly advanced. There are actually methods to fracture a number of wells on the identical time, digitally management fracturing, and use large pumps in a push to chop emissions and prices by phasing out diesel-fueled pumps.

After the 2014 oil worth plunge, price chopping grew to become an obsession and engineers discovered cheaper options.

A decade in the past, operators had been prepared to pay to import sand from Wisconsin primarily based on how they measured the standard of the grains. Now a lot of what’s used is mined close by, just about eliminating the price of delivery, and these fine-grained substitutes appear ok. “We tried junkier sand and saw little to no production loss,” Cramer stated.

While fracture modeling has gotten much more refined, he stated that testing by trial and error is required as a result of it’s so arduous to foretell how a change will prove when pumped right into a formation.

Progress will proceed relying on those that say, “Let’s try it; it sounds crazy, but let’s see how the well produces.”

What follows are highlights from JPT’s protection of modifications in fracturing, drilling, and reservoir engineering over the previous 25 years.

If You Build an Automated Rig, What Do You Tell It To Do?

One imaginative and prescient of the way forward for the oil enterprise within the late Nineties was an image of the primary driller’s cabins made by NOV.

It was an enormous change from the times when drillers labored on the drilling ground with a hand on the brake deal with.

The show screens, joysticks, and high-performance chairs within the new drilling cubicles had been all frequent sights outdoors drilling rigs. But this new command middle was an indication that the digital world had begun to intrude on the largely hydraulics-based world of exploration and manufacturing.

“Prior to my time in the industry the focus in drilling was on more muscle and working harder,” stated Trey Mebane, who now advises startups. Since then, extra muscle nonetheless issues, however so do the digital management programs and information flowing from them.

He was one of many newcomers employed within the mid-Nineties by NOV and different service corporations to make that change. It wanted his information of laptop science and expertise commercialization to assist it promote a brand new technology of apparatus.

Equipment suppliers needed to flip to computer-based digital management programs used broadly in business when it was clear that the gear on the subsequent technology of offshore drilling rigs was too complicated for conventional hydraulic management programs.

When he requested a driller again then concerning the digital shows and the first-generation autodriller, he was advised that was all advantageous. But the most effective factor was working whereas seated on the comfy chair in a climate-controlled cabin. All it lacked was a cupholder—an issue that was quickly fastened.

Source: Trey Mebane.

And Then

What was not apparent 25 years in the past was how the digital information circulation and processing energy required to create this management system would finally result in programmable management programs which have modified the work of drilling engineers.

By 2008, the digital technology in service corporations and oil corporations had created the SPE Drilling Systems Automation Technical Section with a aim of transferring the business towards the day when drilling rigs could be totally automated.

At the time, the concept of pushing a button to drill a properly sounded inevitable. That 12 months, Helmerich & Payne (H&P) launched their long-term effort to assemble and analyze information as the premise for progressive digital management programs. Years later they confirmed the worth of that guess by doubling right down to construct a fleet of FlexRigs which supplied each extra brawn plus brains that decreased downtime for extra environment friendly drilling.

In 2018, after H&P purchased the corporate that made this system, H&P took the next logical step—feeding those commands into the drilling control system for “factory-like consistency,” said John Lindsay.

Innovative operators and repair corporations had been targeted on constructing the automated drilling rig of the longer term. The focus abruptly shifted after the 2014 oil worth crash.

Apache dropped its program to develop a completely automated rig. But not lengthy after that, it began working on ways to drill better by making the most of data, software, and advanced statistical analysis.

“We saw that there was at least a small opportunity to do something more with our rig data—that 1-Hz real-time data—by combining it and mashing it up with contextual data so that it could be something useful,” stated Michael Behounek, the chief of the venture who has since retired and is working as a marketing consultant.

In different phrases, they needed to determine how greatest to handle the job and guarantee these procedures had been adopted. Traditionally the driller was more likely to be told: “There is your bit, go run it, and do your best. This is a vastly different thing,”stated Fred Dupriest, a Texas A&M University professor.

Source: Trey Mebane.

Increasingly, digital management programs on rigs make it attainable to program in greatest practices to make sure they’re adopted. And the job of engineers is to look out for flaws within the system and repair them.

Matt Isbell, drilling engineering advisor for Hess, likened its course of enchancment program to a battle of wits. He stated, “People learn from that and it’s not too long before they have ideas that can be put into practice that can improve whatever the operation is,” in this story.

Over 8 years, Apache’s drilling enchancment strategies delivered 10% year-over-year drilling prices financial savings and had been utilized by rig crews on greater than 1,700 wells in all types of performs.

The probabilistic drilling advisor, although, has its limits. A paper describing the system stated it “only enables the opportunity—it is the field personnel and engineers taking the proper actions and decisions offered by the system that deliver the improvement.”

No Tree Roots, Please

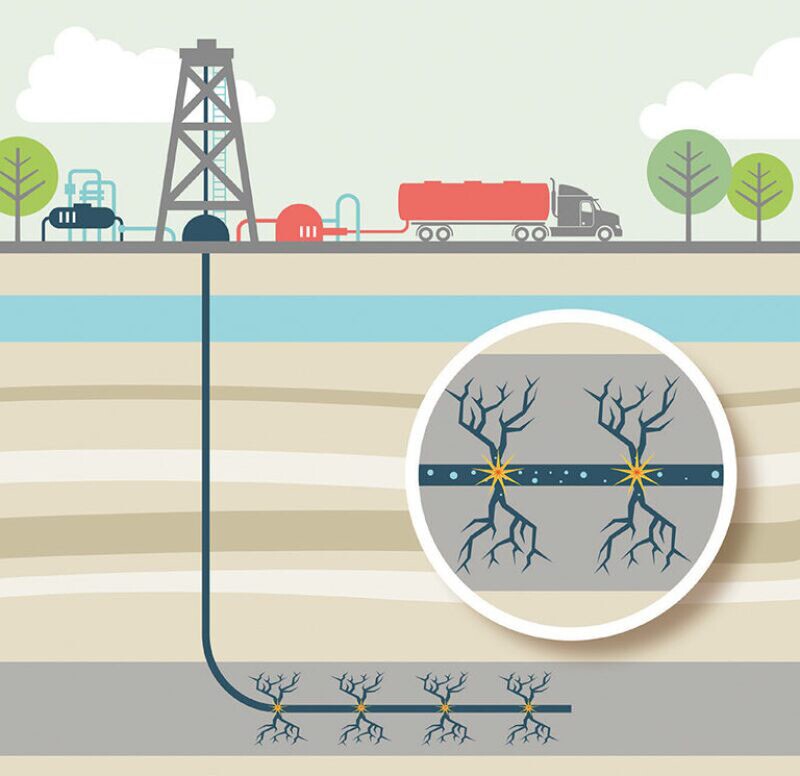

A JPT story in 2015 asked the question: What does a fracture look like?

It was provoked by engineers and geoscientists who had been irked by fracturing illustrations, like Norm Warpinski, a Halliburton fellow, who stated, “They do not look like tree roots. Things do not shatter like glass and run in all directions.”

Others additionally complained about fracturing illustrations that appeared like lightning bolts or tree roots.

While geologists pointed to pure fashions, Mike Smith, the founder and president of the fracturing consulting agency NSI Technologies, stated, “My mental image varies by formation—by the geological environment. It depends on where you are.”

He described the drive of fracturing fluid interactions with a formation. “It goes to hit the first natural fracture and turns whichever way, then goes along until it hits another fracture, splits off again, and starts off across the country.”

In the years since, there have been advances to find methods to watch fracture progress, interactions, and the way they alter over time, together with papers from a collection of fracturing take a look at websites.

Source: FracFocus.

Based on these, an artist would encompass the properly with an enormous variety of fractures—most as skinny as advantageous thread—with a couple of massive cracks out additional. On event a couple of of these can prolong out hundreds of ft.

The form of the fractured space isn’t symmetrical. Sometimes progress is blocked by sizable faults. A depleted zone round an outdated producing properly will appeal to fractures, which can properly hit the opposite properly, decreasing manufacturing for all of the wells.

Recent advances in stress monitoring may even observe fracture progress. Patterns within the sign can outline fracture growth, which has proved extra correct than microseismic.

In appears sure by now that fractures differ.

Perfection Is within the Details

Progress downhole has come from taking note of particulars, usually small ones, equivalent to holes perforated within the casing for strain pumping.

They anticipated to see variations primarily based on earlier analysis utilizing fiber optics indicating the primary perforations in a collection encountered by the fluid resulted in huge fracs, whereas later ones had been hardly stimulated. Downhole photos allowed engineers to see that of their wells. And finally, because the expertise improved, measurements could possibly be made.

That proof led to a interval of experimentation. Ultimately, that led to most operators selecting limited-entry strategies to make sure all of the perforation holes had been stimulated. They targeted on taking pictures uniform holes that restricted flows to higher distribute the water and sand primarily based on plans to pump sufficient water and sand to stimulate all of them.

Flows nonetheless differ, however taking note of these holes has confirmed its worth.

Gummy Bears From Hell

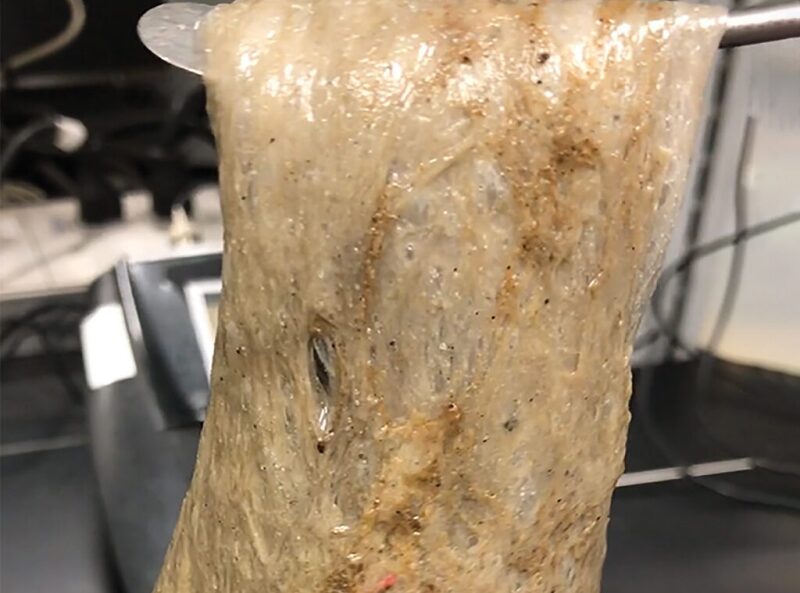

For years, globs of black gum had been flowing up from wells in Oklahoma, usually clogging manufacturing gear.

The source of these “gummy bears” remained a mystery until a story 2020 reported on a paper by Mark Van Domelen, vice president for technology at Downhole Chemical Solutions. He recognized the supply: Iron-rich rock within the wells was interacting with excessive concentrations of sure forms of friction reducers to create a rubbery polymer.

Source: Downhole Chemical Solutions.

The downside was the optimistic cost of the polymers added to fracturing fluid to scale back resistance and infrequently to thicken it to permit it to move extra sand. When phrase obtained out in JPT, producers in different places seen the issues.

Buyers began advising prospects to keep away from formulations with a optimistic cost when reactive chemical substances are current.

It was a small downside for an enormous business, but it surely raised questions on different chemical reactions equivalent to surfactants that shortly degrade within the floor or polymer gunk clogging fracture networks.

George King, a petroleum engineering marketing consultant, supplied a attainable root trigger primarily based on his expertise educating. “Damn friction reducers and iron! Engineers do not understand chemistry!”

Thinking Outside the Lateral

Online mentions of the job initially appeared like one thing {that a} drilling engineer might need carried out on a dare. It turned out to be a option to drill a properly underneath excessive circumstances. The horseshoe properly crammed a niche in a properly pad after the deliberate vertical properly for that lateral couldn’t be drilled as a consequence of extreme mud losses.

They prolonged one other properly on the pad with a curving loop over the 5,000-ft-long path of the second lateral, after which fractured it. It was all carried out with off-the-shelf gear.

“What’s great about this well is not the fact that it’s new, novel, and innovative,” stated David Gibson, cofounder and chief government of drilling market analysis agency Gibson Reports, who adopted the work. “It’s that it starts amazing conversations. Conversations about challenging the status quo—and given the current market and climate, we all need to follow Shell’s lead and think outside the box on all fronts.”

Do Not Slow Down

While the Pace-R801 was stuffed with automated features, “the robot is the one that gets most people interested and excited,” stated Travis Purvis, senior vice chairman, international operations for Nabors Industries.

The amazingly adept robotic drew numerous buyer curiosity, however people are typically nonetheless on the controls in the case of transferring pipe. At an IADC assembly, Paul Pastusek, drilling mechanics advisor for ExxonMobil, supplied a easy clarification: “Humans can move really fast.”

Drilling the Future

In the longer term drillers could also be drilling laterals by granite to warmth steam for geothermal energy vegetation.

If that proves to be true, they might be counting on strategies for quicker drilling developed greater than 25 years in the past by Fred Dupriest, who was then working for ExxonMobil.

The excessive price of drilling in arduous rock has impressed concepts that sound like science fiction, like plasma drilling. But the primary steps towards constructing large geologic heat-transfer programs will deal with off-the-shelf drilling and fracturing gear.

While Dupriest, who taught his technique to drillers on the take a look at website, acknowledged that progress is probably going slower in what he described as “5,000 ft of kitchen countertop,” he added that “the types of issues that constrain the drill rate, and the way you deal with them, are no different.”

Dumping Old Software Friends

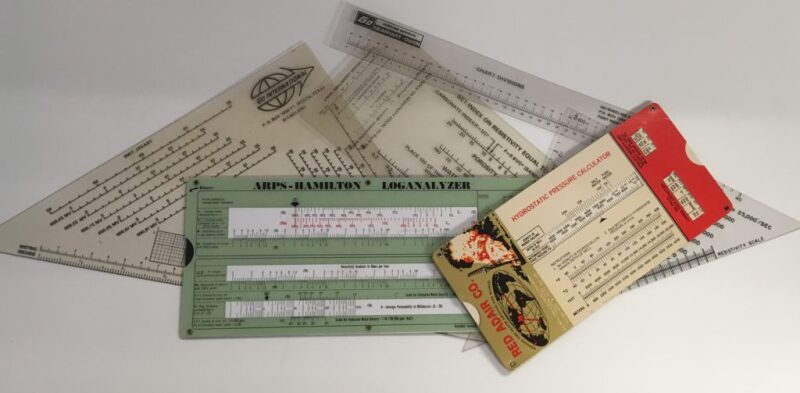

The chief info officer for Chevron, Bill Braun, described it as “the new slide rule.”

The line obtained fun, however he was critical. Like slide guidelines within the Seventies when scientific calculators got here alongside, the venerable database instrument from Microsoft is just not maintaining with a enterprise the place the info units have gotten too massive for it to deal with and are more likely to reside on the cloud.

At the time of that 2020 speech, different applications supplied heavy information administration skills in addition to higher collaboration instruments. It got here at a time when engineers in school had been feeling the necessity to improve their programming and information evaluation expertise to compete in a job market the place operators had been paying shut consideration to digital kills.

Now, there’s one other technology of AI applications constructed round utilizing spoken languages, which may reply to requests, together with writing code, which once more raises questions on what engineers must find out about digital.

Source: Stephen Rassenfoss.

[adinserter block=”4″]

[ad_2]

Source link