[ad_1]

An estimated 200 billion USD is spent each year on baked goods, one of the most popular food markets. As with the majority of food products, production developments, competition, and cultural influences have given consumers a greater range of options than ever before.

The market is highly competitive, with a combination of large global or national companies with smaller local or regional bakeries. Although the expenditure on raw ingredients may seem low, bakeries frequently operate on tiny margins as a result of energy, production, and labor costs.

Around a third of the bakery market consists of bread, where premium products like baguettes and other Italian and French breads are commonly profit and sales leaders. Securing customer loyalty and making consistently high-quality goods is crucial to effective operation.

Quality Control Parameters in a Bakery

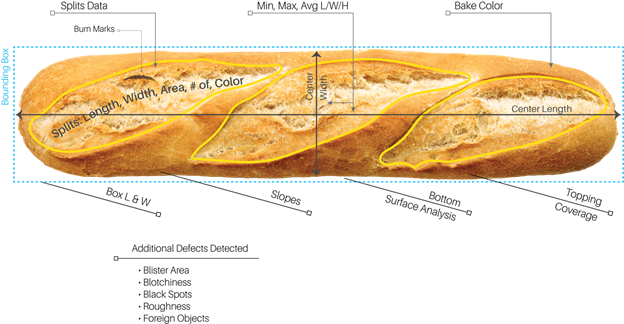

The baguette is a good example. It has a classic appearance and shape and is a highly traditional yeast type bread. The appetizing appearance of the top crust is created by the signature cuts or splits on the baguette.

Baguettes are additionally shaped and baked in pans or free from sheets, which can produce irregularly shaped loaves, appearing like baseball bats or as curved as bananas, which are not the shapes that customers expect. The volume, length, and width must also be consistent. Color is also a critical indication of mouthfeel, baking completeness, and texture.

The majority of modern bread products are partially baked (par-baked) at a factory before being baked at the local bakeries which means it is essential that their color is precisely correct to avoid the final product appearing too light or dark. Particular features of the loaf such as the splits have varied browning features.

Application: 100% Inspection and Rejection of Baguettes

A modern technology that has been utilized by leading bakeries is Sightline Process Control Inc’s automated vision inspection system.

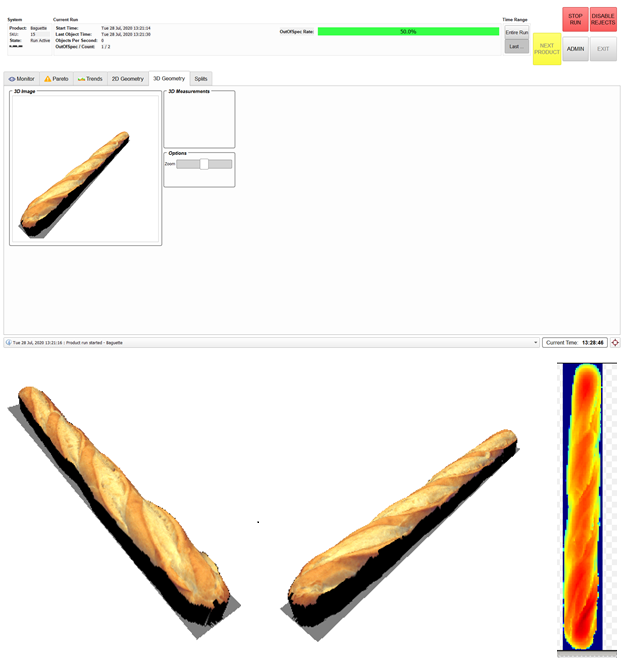

These systems enable a full inspection of each baguette produced by automatically performing almost any possible visual measurement at high speed where it can analyze up to 100 objects each second.

The essential feedback required to ‘dial-in’ the process accurately comes through inspecting each baguette, and the inclusion of automatic rejection ensures that if a defect is identified, it will never reach the customer.

Sightline’s vision inspection systems are all provided with the measura™ software suite which offers more than 100 distinct measurements as standards, such as width, length, height, volume, slope, true L*a*b* color, diameter, and more. New measurements algorithms are added frequently and made available to all systems.

Conventional size measurements performed include:

- 2D Geometry

- Width, length, minimums, maximums, area, averages, and centers.

- 3D Geometry

- Volume (requires correction), height, slopes, predicted weight (requires density factor).

The measura™ software additionally offers measurements of complex product features that are troublesome or impossible to manually quantify, such as contour evaluation and ‘blobs’, offering an objective view of potential threats during the process.

- Blobs

- Baking defects (burns or blisters), toppings, splits, and more.

- Uniquely defined color regions.

- Contour assessment

- Contour imperfections (rips, tails), roughness.

All of the measured parameters can have upper and lower specification tolerance settings, a user-defined target, and upper and lower rejection constraints configured to reject baguettes or sound an alarm depending on the settings.

Vision Inspection in the Bakery

Sightline’s vision inspection technology is available in three systems:

Benchtop – The benchtop system can be simply installed at-line or in a laboratory to make QC assessments automatic or to assist in the development of recipes or product testing aims. A washdown version is also offered.

Overline – Installed directly over current conveyors, the overline system offers 100% inspection from the top for the continuous monitoring of quality.

In-line – The in-line system is tailored to be installed directly into a current production line. It offers 100% inspection and automatically rejects products that do not meet specifications.

Each of the systems is provided with the measura software suite, comprising of the following apps:

- measura Inspection – operations and measurement software

- measura Toolbox – product measurements can be intuitively configured

- measura Analytics – provides detailed reporting features

- measura Dashboard – offers remote monitoring of important limits and parameters on any device anywhere in the plant

Sightline vision inspection systems are manufactured in Ottawa, Canada, and are supported by an international team of applications and vision inspection experts.

Figure 1. In-Line System.

Figure 2. Par-baked baguettes passing through the vision inspection system.

Figure 3. 3D Height Analysis.

This information has been sourced, reviewed, and adapted from materials provided by Sightline Process Control Inc.

For more information on this source, please visit Sightline Process Control Inc.

[ad_2]

Source link