[ad_1]

Concepts and applied sciences for rock burst prevention and management in TBM building are proposed based mostly on the current understanding of the traits and legal guidelines governing rock burst, mixed with the structural traits and building strategies of TBM.

Target of rock burst prevention and management in TBM building

As a pure geological phenomenon beneath sure situations, rockburst has a big influence vitality when it’s robust, and its prevalence is sudden and unsure. Although some prediction theories and monitoring strategies exist to help this purpose, it nonetheless stays tough to precisely decide when, the place and the way a lot vitality rockburst will happen upfront. Even if the prevalence of rockbursts is predicted precisely, different dependable prevention and management applied sciences have to be carried out to make sure the protected crossing of TBMs. Therefore, the prevention and management goals of rockburst should be goal and practical, and the advantages of security and pace should be absolutely thought-about based on the grade of rockburst. Toward offering options for numerous ranges of rockburst based mostly on the affect diploma of the delay of advance pace, the workload of help and later restoration, and the hurt of apparatus and personnel, the next prevention and management goals of rockburst classification are proposed.

-

(1)

Prevention and management targets of slight rockburst. After the well timed and dependable implementation of prevention and management technical measures, the affect of comparable class-III surrounding rock help on TBM excavation delay was decided. Rock bursts and the implementation of prevention and management measures have little influence on TBM footage pace. Rock burst and collapse within the cave wall may be managed with out damaging the supporting construction. There isn’t any additional slag cleansing workload to keep away from the harm of rock bursts to tools and personnel.

-

(2)

Prevention and management targets of medium rockburst. After well timed and dependable implementation of prevention and management technical measures, the affect of comparable class-IV surrounding rock help on TBM excavation delay. Rock bursts and the implementation of prevention and management measures have a fantastic affect on the penetration pace of TBMs. The cave wall burst and cave-in and rock ejection have been principally managed. The carried out supporting construction is not going to be broken. There is principally no additional slag cleansing workload. The harm of rockbursts to tools and personnel must be averted.

-

(3)

Prevention and management targets of robust rockburst. After well timed and dependable implementation of prevention and management measures, the affect of comparable class-V surrounding rock help on TBM excavation delay. Rock bursts and the implementation of prevention and management measures have a fantastic affect on TBM footage pace. The deep blasting, influence ejection and falling rock of the cave wall are managed to a sure extent. The supporting buildings in particular person positions are broken, and the workload of restoring help shouldn’t be nice. Rock bursts must be averted from inflicting nice harm to tools. Avoid private damage.

-

(4)

Prevention and management targets of extraordinarily robust rockburst. After well timed and dependable implementation of prevention and management measures, the affect of comparable V-level extraordinarily damaged surrounding rock help on TBM excavation delay. Rock bursts and the implementation of prevention and management measures have tremendously decreased the penetration pace of TBM building. The rock mass collapsed on a big scale, and the supporting buildings in particular person positions have been broken, so the workload of slag cleansing and supporting restoration was heavy. The security menace of rockburst influence and falling rocks to personnel and tools has been principally managed.

Criteria of rock burst prevention and management in TBM building

Common engineering practices present that even when there’s good rock burst prevention and management expertise, it’s tough to realize good prevention and management results if the technical scheme can’t be chosen and carried out based on sure theoretical standards. For instance, the help can’t be accomplished on the proper time, or the technical scheme can’t be chosen based on the rock burst grade. Therefore, prevention and management of rockburst should first contemplate the traits of TBM building and the legislation of rockburst prevalence and comply with the proper idea and theoretical standards of rockburst prevention and management. Four theoretical ideas of rock burst prevention and management are proposed based mostly on the traits of TBM building, the traits and legal guidelines of rock burst prevalence and the sensible expertise of rock burst prevention and management in engineering.

-

(1)

Construction pace management criterion. The building pace management as used right here refers to controlling the footage every single day or inside a sure time frame. On the one hand, as talked about above, the development pace of a TBM has a big influence on the situation of robust rockbursts. On the opposite hand, contemplating the area–time impact of rockburst, if the development pace of TBM is just too quick, the supporting prevention and management measures are too late to be accomplished earlier than rockburst happens. Regardless of how good the prevention and management expertise is, it is going to nonetheless have the implications of rockburst and produce the chance of apparatus and personnel damage. The great amount of slag removing restricts the footage pace. Therefore, based on the prevalence stage of rockburst and the traits of help prevention and management expertise, it is very important actively management the driving pace, and the development pace management standards must be adopted.

-

(2)

Risk management standards. The idea of threat as used right here refers back to the threat introduced by rock bursts, that’s, the security threat of rock bursts to TBM building personnel and tools and the chance of the influence of TBM building pace, building interval and trapping. The corresponding prevention and management technical measures shall be taken based on the magnitude of threat hazards and the likelihood of prevalence. This is completely different from the management idea of the fault fracture zone. It is usually possible and efficient to implement technical measures equivalent to help after the tail of the TBM defend is uncovered within the fault fracture zone. For rockburst, whether or not it’s the results of rockburst prediction idea or the results of rockburst monitoring, it provides a chance of rockburst and a normal stage prediction. It ’can not attain and obtain a really correct forecast stage. However, critical penalties will outcome if technical measures usually are not taken in time earlier than the rock burst. Therefore, even whether it is confirmed that there isn’t a actual rockburst within the tunnel part at this location after excavation, there’s a excessive likelihood of rockburst so long as it’s judged based on the prediction outcomes and the expertise of comparable rockburst surrounding rock situations within the early stage of this challenge. It is important to take corresponding help and different technical measures to forestall and management rockbursts. This step represents a threat management measure. It can’t be thought-about that such prevention and management measures are waste. Simultaneously, the corresponding building interval and value loss should be thought-about and acknowledged. Therefore, the prevention and management of rockburst is a safety measure taken upfront based on the potential for prevalence, and it’s essential to comply with the chance management standards of rockburst.

-

(3)

Temporal and spatial management criterion. Engineering practices present that rockburst might happen immediately or in a short while after excavation, which is named on the spot rockburst. This sort of rockburst primarily happens within the tunnel face and TBM cutter head or defend space. Rockburst can also happen after a interval of delay after excavation. As talked about above, the likelihood of such a rockburst occurring inside 24 h could be very excessive. Individual prevalence over an extended time frame. The location is principally concentrated within the TBM host space. For instant rockburst, rockburst principally happens within the vary of the tunnel face and defend physique. We can finest leverage the traits of the TBM host construction to implement corresponding prevention and management technical measures. It can be essential to design the cutter head, cutter, bucket tooth and defend robustly. For a rockburst with a protracted lag time, it’s mandatory to totally grasp the temporal and spatial legislation of rockburst, coordinate the driving footage and help pace of the TBM, and actively management the footage pace to regulate the situation of the rockburst. Support measures must be carried out in correct time and area earlier than TBM rockburst, and mandatory personnel and tools safety design must be made for the TBM host space. Therefore, the prevention and management of rockburst ought to contemplate the area–time impact and comply with the area–time management criterion.

-

(4)

Graded management criterion. Different surrounding rock situations have completely different rock burst grades. Rockbursts are usually divided into no rockburst, slight rockburst, average rockburst, robust rockburst and even extraordinarily robust rockburst. Different rockburst grades have completely different hazards. Different prevention and management technical measures have completely different prevention and management results. The ensuing affect on the development footage pace and the development price are completely different. The technical measures for the prevention and management of minor and average rockbursts might not resolve the basic downside of robust rockbursts and very robust rockbursts. Therefore, we can not discuss concerning the technical scheme of rock burst prevention and management generally. According to the rock burst grade, completely different rock burst prevention and management technical schemes must be chosen. At current, regardless of some engineering expertise in overcoming these points, there stays a scarcity of systematic theoretical steerage on how to decide on the technical scheme of rock burst prevention and management. It is thus mandatory to determine a theoretical system for choosing prevention and management schemes at completely different ranges. The rock burst graded management criterion must be adopted in TBM excavation.

Prevention and management expertise of rock burst in TBM building

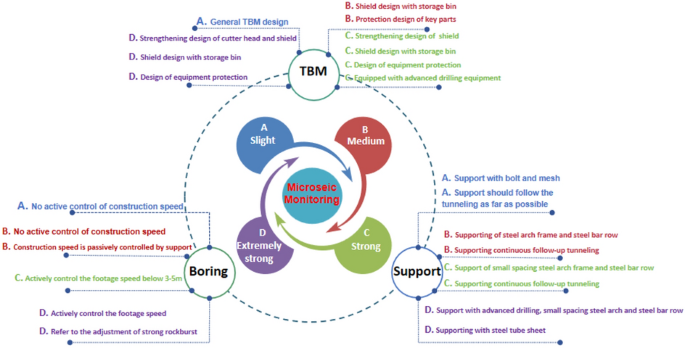

A technical system for categorized prevention and management of rock burst in TBM building based mostly on coordinated management of apparatus excavation help is proposed right here based on the affect legislation, area–time impact, accessible tools construction and building technique traits of TBMs on rock burst, in addition to the prevention and management goals and pointers of rock burst. Compared with open TBMs, shield-type TBMs usually extra simply forestall and management rockbursts, and the management is comparatively easy as a result of the primary engine space is protected by the defend and the again supporting half is supported by prefabricated segments. Therefore, the next primarily discusses the technical scheme of rock burst prevention and management with the open TBM.

Rockburst prevention and management expertise of various grades

For slight rockburst, the standard open TBM is provided with an anchor drilling machine on the tail of the defend, which is handy for anchor operation. Moreover, the mixed help of the bolt and mesh can resist slight rockburst. The operation pace of the bolt and mesh help can be comparatively quick. Basically, it may possibly sustain with the TBM excavation; even when it can not sustain with the excavation for some time it is going to usually not convey the security menace of apparatus and personnel and might even treatment the help. Therefore, it’s not essential to actively management the pure tunneling pace of the TBM, however it’s mandatory to make sure that the help follows tunneling. Rock burst prevention and management help may very well trigger some delay to TBM building pace, i.e., footage pace. If the rockburst happens in entrance of the defend tail, it’s a large-scale steady rockburst. In this case, the usage of anchor rods and metal mesh is invalid as a result of it is going to trigger a considerable amount of slag to be cleaned. The technical scheme of the mix of an arch body and a metal bar row with a big spacing must be adopted. It not solely ensures security and reduces slag falling but additionally tremendously improves the development pace. According to the above evaluation, the technical prevention and management scheme of minor rockburst is a mixture of typical TBM design and bolt mesh or large-spacing arch reinforcement row help and help following excavation with out actively controlling the footage pace. For average rockburst, peculiar bolts and mesh help have problem resisting the influence of rockburst. The help by spraying concrete on the primary engine of the TBM will pollute the primary engine, and the power will improve slowly. It shouldn’t be a sensible choice until concrete with low value, no rebound and excessive pace may be developed. Therefore, it’s proposed that the continual closed help technique combining a metal arch body and metal bar row is adopted for average rockburst. In this case, the TBM building pace doesn’t have to be actively managed. Because the help might not sustain with the excavation, the development pace might be passively managed. In addition, to allow the TBM defend to retailer metal bars and obtain uninterrupted closed help, it must be designed as a defend with a storage interlayer. Thus, the medium rockburst prevention and management technical scheme is constructed, which incorporates the design of a storage bunker defend, the help of an arch reinforcement row with common spacing and the passive management of excavation. For robust rockburst, previous engineering observe exhibits that typical metal arch help has problem resisting the influence of robust rockburst. Support is usually broken. In addition, a number of slag cleansing work might be introduced. It threatens the security of apparatus and personnel and significantly impacts building progress. Nevertheless, based on the evaluation outcomes of the traits and legal guidelines of rockburst, the energetic management of the day by day footage within the case of robust rockburst has a big influence on the situation of rockburst. Therefore, most robust rockbursts can happen within the face and defend space by actively controlling the day by day footage. In this fashion, not solely the tools and personnel behind the defend are protected. It is extra vital that the issue of rock burst safety with monumental influence vitality may be reworked into the issue of landslides and damaged zone help. Namely, the rockburst and its falling rocks fall within the space from the tail of the defend to the entrance face, and the cutter head and defend play a task in resisting the influence of rockburst. Small-spacing metal arches and metal bars may be mixed on the tail of the defend to help rockburst and rockfall. On this foundation, a robust rock burst prevention and management technical scheme is proposed, which mixes the design of a strong cutter head defend, energetic management of footage pace and metal bar row help of a small spacing metal arch body. Generally, the gap from the tunnel face to the defend tail is roughly 6 m, and greater than 90% of robust rockbursts happen inside 24 h. According to this legislation, the day by day footage of TBM excavation may be actively managed beneath 3 ~ 5 m. With the excavation course of, the mixed help of the metal arch body and metal bar row on the tail of the defend follows intently. After the footage management index is accomplished, the machine can cease and wait. The spacing between metal arch frames is decreased to allow the crossing of TBM help sneakers. If the smaller spacing can’t be crossed, concrete pouring can be utilized to easy it. For extraordinarily robust rockbursts, there are literally native extraordinarily robust rockbursts within the robust rockburst tunnel part of the Han-Ji-Wei Water Diversion Project. The idea and expertise of rock burst prevention and management may be managed close to robust rock bursts. The particular footage pace index, arch spacing and mannequin may be adjusted appropriately. Simultaneously, a water hammer drilling rig geared up with a TBM can be utilized to conduct superior drilling to degrade the extraordinarily robust rockburst vitality. Then, the tunneling help technique talked about above is adopted for crossing. In addition, a double-type help TBM can be chosen. Applied with the normal open TBM approach, this strategy provides a metal sheet installer and an auxiliary propulsion system, which is intently behind the defend to help the metal sheet. This operation additional improves the security and building pace of TBM crossing robust rockbursts. However, its drawback is its excessive price.

The technical schemes of rock burst prevention and management with completely different grades are proven in Fig. 8.

Engineering software impact of graded rockburst prevention and management expertise

The technical scheme of the prevention and management of minor rockbursts has been absolutely utilized within the Xinjiang ABH challenge and Xinjiang EHe (EH) challenge. The ABH challenge in Xinjiang had 101 slight rockbursts by August 2019. The rock burst may be fully managed by the help, and no tools harm or casualties have occurred. Because of the compressive power and integrity of the encompassing rock of the ABH challenge, it’s simple to tunnel. The building pace beneath slight rockburst is roughly 70–90% of that with out rockburst. In the Xinjiang EH challenge, a big space of steady minor rockburst to average rockburst occurred in entrance of the defend tail, and the slight rockburst adopted the technical scheme of mixing long-distance arch frames and metal bars. In the sphere software of tunneling for a number of kilometres, the impact is obvious, the security is managed, and the month-to-month footage can attain roughly 400 m.

In the ABH challenge and the YHJW challenge, the monitoring and prediction of rockburst microseisms embrace average rockburst, slight-moderate rockburst or moderate-strong rockburst, all of which undertake the abovementioned rockburst prevention and management technical scheme. From the beginning of TBM excavation within the ABH challenge to August 2019, there have been 18 slight-moderate rockbursts and 32 average rockbursts. From excavation to November 2019, there have been 84 slight-moderate rockbursts, 158 average rockbursts and 80 moderate-strong rockbursts within the YHJW challenge. By adopting the above prevention and management technical scheme, the help resisted the influence of rockburst, no casualties occurred, and the tools was not tremendously broken. Moreover, this scheme achieved a comparatively quick TBM building pace, which is roughly 50%—70% of the development pace that’s achieved with out rockburst. The day by day footage is roughly 10 m when the metal arch body and metal bar row are used for help within the ABH challenge.

In the Lingnan part of the YHJW challenge, with growing burial depth, it started to enter the continual robust rockburst space and even the extraordinarily robust rockburst space after the TBM entered the second excavation part.

By the top of October 2020, the second excavation part had accomplished a 2075.3 m excavation, and there have been 813 rock burst sections that restricted excavation and triggered shutdown help, with a complete size of 2023.6 m, accounting for 97.5% of the excavated size. The TBM efficiently handed by the robust rockburst tunnel part of greater than 2 km by adopting the prevention and management scheme of rockburst by actively controlling the day by day footage. However, roughly 7% of the secondary delayed rockbursts occurred within the arch and backside arch. There have been 37 rock bursts with robust lag within the arch and 21 rock bursts with lag within the backside arch, which triggered harm to the supported structural system. However, delayed rockburst occurred within the supported space. The menace to personnel and tools is tremendously decreased, which primarily brings the workload of help restoration and slag removing. The common month-to-month footage of the TBM in a robust rock burst tunnel reaches 110 m, and the day by day footage is roughly 3.5 m. The TBM safely passes by the long-distance robust rock burst tunnel part. Simultaneously, the TBM cutter head and defend additionally proved to have the ability to face up to the influence of robust rockburst. Since the TBM was initially designed based on the conference, the cutter head and defend have been considerably broken, however not sufficient to trigger deadly issues. The TBM cutter head and defend ought to due to this fact be designed robustly based on the prevention and management scheme of robust rockburst proposed on this paper.

The software of double-type help TBMs within the building of plateau railways gives one other technical means for TBMs to cross extraordinarily robust rock bursts. There isn’t any engineering case listing of metal pipe segments in coping with extraordinarily robust rockburst, however the metal pipe segments in coping with giant deformation of sentimental rock within the Xinjiang EH challenge have been verified by engineering, and the impact is excellent.

The precise impact of engineering software of graded rockburst prevention and management expertise is proven in Fig. 9.

[adinserter block=”4″]

[ad_2]

Source link