[ad_1]

While water use has at all times been a problem, it was solely within the late Nineteen Nineties that unchecked water use within the oil subject grew to become a priority, with the business competing with agriculture and cities for clear water provides. Hydraulically fracturing shale formations introduced the nation power independence, however it additionally highlighted the massive quantity of water wanted to efficiently execute the method.

In the final decade, this was additional exacerbated by buyers wanting greener, extra environmentally pleasant corporations to spend money on. The good nexus of environmental stewardship, modern know-how and good enterprise practices introduced scientists’ considering out of the field whereas adapting applied sciences from different industries.

Traditional water therapy. Microbial management has at all times been a main concern for completion water. Water sourced from conventional water storage amenities, resembling pits and ponds, requires efficient microbial management previous to introduction to the wellbore, as that is important for a wholesome formation. Choosing the flawed resolution for water therapy can lead to costly harm to tools, a excessive micro organism load pumped downhole, and a probably bitter properly.

Traditional oil and fuel microbial therapy options could be divided into two varieties. One includes oxidizers that present economical, quick micro organism management. However, many corporations frown upon oxidizers, since the most typical of them is chlorine dioxide, a unstable, flammable fuel that presents vital publicity hazards to wellsite personnel and accelerates corrosion.

The second kind contains standard biocides and preservatives, resembling glutaraldehyde (glut), quaternary ammonium compounds (quat), glut-quat blends and aldehyde-releasing compounds. These standard chemistries present a longer-lasting resolution however are dearer and slower-acting, and customers can not receive instant suggestions on efficacy.

A brand new chemical oxidant know-how, initially developed for the meals and beverage business, incorporates a 5.8% resolution of sodium peracetate, formulated to ship massive concentrations of reactive oxygen species (ROS), which improve product efficiency. This distinctive oxidant gives a protected, economical various for upstream water therapy with out the hazards or price of conventional oxidizers or standard biocides. The new oxidant gives speedy therapy and could be mixed with the complementary use of standard biocides for lengthy lasting outcomes.

Originally developed for industrial water therapy, reuse and sanitization, this new oxidant know-how was first proposed for the meals and beverage business, the place it wanted to clear quite a few regulatory hurdles earlier than adoption. However, a faster-to-market strategy was supplied by early adopters in an business sometimes not identified for quick adaptation of recent know-how: the oil patch.

Chemistry. At the properly web site, on-demand manufacturing of the brand new oxidant happens by reacting three secure, non-flammable feedstocks collectively in a particular course of to create the distinctive formulation. This formulation constantly transforms “activated” peracetate into a mixture of reactive oxygen species (ROS), together with singlet oxygen, which is molecular oxygen in an excited state. Formulated in water, the ROS “supercharges” the oxidative exercise of the dad or mum peracetate (with out the usage of gentle or catalysts for activation). The energetic peracetate-singlet oxygen resolution is generated on web site, as a result of its quick half-life (roughly 1.5 hours (hr) for focus), in distinction to chlorine dioxide that’s generated on web site, as a result of it’s too harmful to move.

The mixture of reactive oxidizing species gives enhanced efficiency whereas producing a major oxidation-reduction potential signature that may be monitored and correlated to focus or efficacy in a therapy course of. By its nature, singlet oxygen is short-lived in water and reacts shortly with sure sorts of supplies however not with others. This distinctive selectivity, compared to hydroxyl radical, ozone or chlorine, permits it to do particular jobs within the presence of supplies, together with salinity, oil, polymers and quite a few water therapy chemical substances. This means that you can selectively goal the oxidation of undesirable supplies. You don’t essentially need to break down every thing that’s within the water; for instance, a friction-reducing polymer crucial for a profitable frac therapy.

Since this new therapy know-how is primarily a dilute resolution of a peracetate salt, it’s an inherently safer oxidation chemistry that’s basically non-volatile and odorless. The peracetate-singlet oxygen resolution is dosed into the water stream, routinely, on the prescribed proportion for the present flowrate and water high quality, primarily based on information from in-line flowmeters and oxidation discount potential (ORP) sensors. Oxygen is slowly launched from any unconsumed oxidant, leaving non-toxic, biodegradable residuals which are usually acknowledged as protected (GRAS designated by the FDA).

Laboratory testing. The selective reactivity of peracetate-singlet oxygen chemistry is helpful for avoiding corrosion and degradation of apparatus and supplies. The inherent selectivity makes the chemistry much less aggressive towards delicate metals, polymers and elastomers. Extensive lab testing established the selectivity of the formulation to focus on contaminants over different supplies.

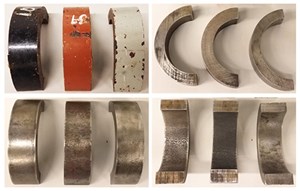

Fig. 1. Three coupon varieties examined: earlier than preparation (high left panel) and after preparation.

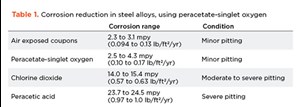

A latest examine in contrast the corrosion charges between the usual benchmark of dissolved oxygen (DO), chlorine dioxide, a peracetic acid product and the peracetate-singlet oxygen formulation at comparable energetic oxidant concentrations. Relative comparisons had been made underneath managed situations in temperature-controlled, circulating immersion baths outfitted with automated make-up chemical feeds in a laboratory setting.

Corrosion coupons ready from high-pressure-pumping pipe sections had been supplied by a third-party oilfield providers firm. Three coupons, representing three pipe varieties/alloys, had been designated by a coating shade on the outer floor of the pipe (black, brown, and gray) and subjected to every check bathtub situation. One set of three coupons ready for testing is proven in Fig. 1.

Fig. 2. Coupons after 400 hr of publicity previous to cleansing. Black, brown and gray varieties, left to proper. Dissolved oxygen (high row). Peracetate-singlet oxygen (second row), chlorine dioxide (third row), peracetic acid (backside row).

Three pipe varieties/alloys had been chosen and examined

to check corrosion charges, extent of pitting, and different habits when uncovered to five% brine options containing oxidants in circulating immersion baths at 115°F. The management bathtub contained dissolved oxygen from air (common close to 4.3 mg/L O2), whereas comparisons had been made for the peracetate-singlet oxygen formulation (common close to 10 ppm energetic peracetate), chlorine dioxide (common close to 9 ppm energetic ClO2) and peracetic acid product (common close to 8 ppm energetic PAA). Three coupon varieties had been completely cleaned and uncovered to every of the three chemistry situations for a complete of 400 hr.

During the exams, the air uncovered coupons passivated with ferric oxide blended with a skinny layer of mineral scale, whereas the peracetate-singlet oxygen formulation-exposed coupons passivated with ferrous oxide blended with a skinny layer of mineral scale. The ClO2 and PAA uncovered coupons didn’t passivate considerably and skilled probably the most extreme corrosion. After 400 hr, the coupons had been cleaned to take away iron oxides and scale deposits, measured for weight reduction, and evaluated for pitting. The outcomes are proven in Fig. 2 and Table 1.

Testing has proven that peracetate-singlet oxygen, when in comparison with different oxidizing water therapy applied sciences, successfully reduces corrosion in metal alloys utilized in pressure-pumping tools for hydraulic fracturing operations, Table 1.

WELLSITE TREATMENT

Water therapy for hydraulic fracturing. Untreated water laden with micro organism may cause issues within the formation and with the tools. If left untreated, the micro organism will multiply downhole, thus rising the issues. A peracetate-singlet oxygen chemistry treats water used throughout hydraulic fracturing, so the water doesn’t include micro organism that may contaminate the formation or harm tools. Water is handled on the floor previous to the frac job. The provide reservoir can be handled for quicker, extra persistent micro organism management.

Produced water therapy for reuse. Ideally all produced water—water returning again uphole after the frac therapy—needs to be handled for reuse on the subsequent frac job. Peracetate-singlet oxygen chemistry gives microbial management to deal with water produced by the frac therapy, eradicating microbes and different contaminants from downhole, so they aren’t launched into one other properly.

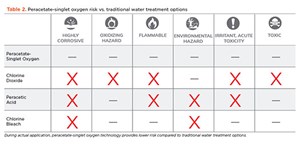

Water therapy previous to injection. A 3rd, lesser use includes treating produced water earlier than it’s injected in saltwater disposal wells (SWD), Table 2. Peracetate-singlet oxygen chemistry can take away micro organism from wastewater earlier than it’s injected in saltwater disposal wells. Bacteria may cause corrosion and souring within the SWD system, necessitating tools restore and substitute.

During precise software, peracetate-singlet oxygen gives decrease threat, in comparison with conventional water therapy choices. (Hazards exhibiting empty cells within the desk will not be relevant to the listed chemical.)

CASE HISTORY

A significant E&P operator, working from a multi-well horizontal pad within the Permian basin, recognized an issue with excessive quantities of corrosion on its service supplier’s frac iron, inflicting frequent tools restore and substitute. Clean Chemistry was engaged to substantiate the reason for the corrosion and the relation to the water high quality getting used. It was discovered that the chemistry being pumped brought about a decrease pH within the fluid and was an element resulting in the corrosion. Additionally, chemical residue left after the therapy brought about corrosion. The firm advisable a therapy program of its proprietary formulation of peracetate-singlet oxygen, together with a sophisticated wellsite dosing skid containing inside software program to enhance service high quality with main accountability and information transparency.

This various resulted in a safer, simpler water therapy program for each efficacy and price to the operator. The shopper’s earlier frac program used water therapy with peracetic acid charges of 100 or extra ppm focus of energetic elements. The product decreased the energetic product use to fifteen to twenty ppm and achieved higher outcomes that retained the pH stage of frac therapy water, left no detrimental residual chemical quantity, and lowered tools corrosion. It additionally helped preserve the efficiency of the friction reducer.

Results had been enhanced by an onsite dosing skid extra superior than present competitor models. The onsite dosing program makes use of proprietary software program for automated onsite era and introduction of the chemistry into the water stream. Service high quality is enhanced by an array of inline sensors that present instantaneous information for elite-level service high quality. Key efficiency indicators are monitored in actual time by a 24/7 devoted high quality workforce to make sure job efficiency is maintained, and operations run easily all through the job.

The outcome was much less restore and substitute of frac iron, in addition to efficient, high quality water therapy. Cost financial savings had been additionally realized through the use of a safer, simpler chemistry for water therapy. The shopper was glad with the outcomes and plans on utilizing this resolution for different wells within the space.

BENEFITS

A shortage of unpolluted, contemporary floor water will solely turn into extra acute sooner or later. Reducing freshwater use on the wellsite will take away competitors with agriculture and municipalities for this beneficial commodity. Benefits will even be achieved by way of tools safety, decreased prices and environmental safety, plus the additional advantage of no residual results.

Asset safety. Better microbial management reduces tools contamination and corrosion that may result in expensive tools restore or substitute. This is particularly true throughout frac therapies, the place dangerous elements within the water can contaminate the massive quantities of iron, pipe and casing which are uncovered to the water. The new chemistry additionally removes biofilms that may clog injectors on waterfloods.

Wellsite economics. Lower quantities of produced water injected into disposal wells will lower related transportation prices. This contains the precise transportation prices (vehicles or pipelines), the injection course of and regulatory and allowing prices. The course of lowers toxicity ranges of handled water and removes contaminants that may shortly clog disposal wells.

Environmental. The new course of doesn’t include chlorine, chlorate, chlorite, chloride, sulfate or phosphates. It contributes much less natural carbon than peracetic acid and avoids formation of trihalomethanes (THM), haloacetic acids (HAA) or different poisonous halogenated organics. These attributes guarantee decrease environmental impacts and assist to fulfill limits on salts, phosphorus, BOD and disinfection byproducts.

No residual results. Any residual materials is quickly biodegradable and isn’t persistent within the setting. According to the FDA designation, the residual materials is usually acknowledged as protected (GRAS). It doesn’t immediately kind poisonous halogenated, chlorinated byproducts from water therapy, particularly in consuming water.

Singlet oxygen-generating therapy know-how can also be tailored to be used in paper mills, in water cooling techniques and within the meals and beverage business.

TRAILER MOUNTED SYSTEM

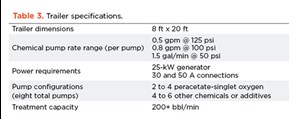

A brand new trailer-mounted system, launched in Q2 of 2023, gives an easier, smaller tools footprint, with much less capital funding for water therapy to any venture web site no matter location, Fig. 3. The enhanced trailer design features a proprietary tools bundle, whereas a regular design means the unit is well manufactured to fulfill the demand of water therapy in any business, Table 3.

The new cellular therapy trailer has a number of key options that improve water therapy within the subject, together with:

Chemical dosing capability. Chemical dosing pumps (as much as eight) for oxidants, preservative biocides, scale inhibitors, clay management, surfactants and extra. Chemicals could be dosed immediately into the water stream, and the chemistry could be blended to suit the particular job necessities. Chemical charges and make-up could be modified to match altering job parameters or adjustments within the therapy plan. A single trailer unit can service zipper and simulfracs with excessive water use charges.

Automation. Inline high quality sensors and pump flowmeters observe high quality and management exact chemical therapy. Dedicated flowmeters management and monitor chemical consumption.

Connectivity. Real-time reporting contains cloud-backed monitoring of therapy efficiency information from inline water high quality sensors, chemical era statistics and automatic day by day stories.

Autonomous, remotely monitored operation. All Clean Chemistry water therapy trailers incorporate distant monitoring and management by QA/QC specialists. Specialists can intervene remotely for steady therapy in case of system alerts and alarms. Currently, most trailers for frac-on-the-fly water therapy jobs are staffed, whereas a lot of the jobs for treating produced water are unmanned.

Simplified logistics and deployment. The new trailer-mounted system means jobs are extra simply scheduled, and crews and trailer are stored busy. Units can choose up and go to the subsequent location; upkeep is carried out within the subject. Units could be on web site for so long as wanted, from a number of weeks to a number of months. The trailer could be arrange in as little as 4 to six hr, if crucial.

VALUE PROPOSTION

It is less expensive and sustainable to make use of recycled water, in comparison with buying contemporary water and/or disposing of produced water. A sound water therapy program that can be utilized in any space negates the disparity of water price in several areas. Water reuse lowers the price of operations, so there may be extra finances to make water therapy extra economically possible. Peracetate-singlet oxygen is a safer, greener and simpler oxidation chemistry, in comparison with conventional oxidizers and preservative chemistries.

About the Authors

Dr. Wayne Buschmann

Clean Chemistry

Dr. Wayne Buschmann is chief know-how officer and founding father of Clean Chemistry. Originally from Massachusetts, he obtained a BS diploma in chemistry from the University of New Hampshire, a Ph.D. in chemistry from the University of Utah, and has held a post-doctoral place on the Los Alamos National Laboratory in New Mexico. After Los Alamos, he joined a contract analysis and growth firm in Colorado, the place he raised funds and grew a water know-how program for a number of years. Dr. Buschmann then began creating an unbiased start-up to invent core applied sciences that had been foundational to forming Clean Chemistry in 2012. To date, he has co-authored over 20 peer-reviewed technical publications, is a main inventor on 25 patents, is a member of the American Chemical Society and TAPPI, and serves on the board of administrators for a neighborhood municipal water district.

Related Articles

[adinserter block=”4″]

[ad_2]

Source link