[ad_1]

Background of low-level grouting filling check

Dahaize Coal Mine is situated west of Yuyang District, Yulin City, Shaanxi Province. The industrial website of the mine and the coal preparation plant are organized individually and related by a 3.0 km trestle. The designed manufacturing capability of the mine is 15.0Mt/a, which adopts full vertical shaft growth and zonal air flow, and is provided with two vital mining peak totally mechanized working faces. Dahaize Coal Mine is a brand new mine. Currently, working face 20101 in panel 201 is being mined, and dealing face 20201 in panel 201 is being organized. The sand, gravel, and different supplies used for concrete manufacturing underground shall be vertically fed by the No. 1 blanking gap and No. 2 blanking gap.

According to the present state of affairs of mine building, underground mining, and coal preparation plant, the gangue of Dahaizi Coal Mine primarily comes from the tunneling gangue through the capital building interval and the washing gangue of the coal preparation plant, with the quantity of washed gangue about 0.7 Mt/a. According to the preliminary design of the mine, all of the coal gangue through the building of the Dahaize Coal Mine is used to put the particular railway subgrade for the mine. Furthermore, the washed gangue is handled with the know-how of filling goaf with coal gangue slurry.

Simulation check of low-level grouting filling

To discover the feasibility of low-level grouting filling and its slurry intervention legislation, a simulation experiment of low-level grouting filling was carried out within the gangue hill of Dahaize Coal Mine, analyzing the move and diffusion legislation of gangue slurry within the simulated goaf throughout low-level grouting.

Simulation mannequin for gangue accumulation in native caving zone

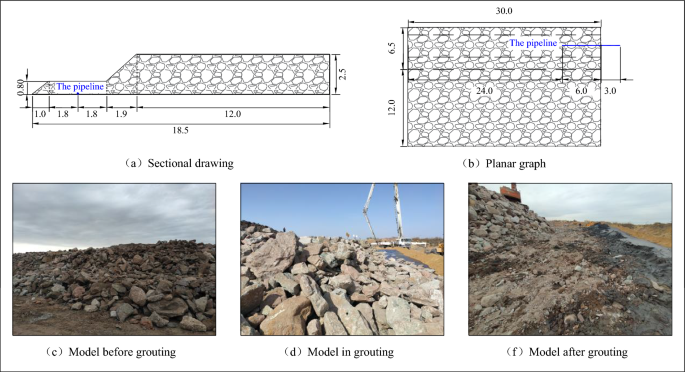

Based on the stepped rock block collapse accumulation traits within the decrease a part of the arc-shaped triangular space after the extraction of coal seam 2 in Dahaize Coal Mine and low-level grouting filling space, the rock block collapse morphology of the buildup caving zone is simulated on the bottom. The total mannequin is stepped, with a dimension of 30.0 m × 18.5 m × (0.8 –2.5) m, the low-level grouting pipe is laid on the backside of the mannequin, and the boundary of the mannequin is constrained by sand, as proven in Fig. 5.

Simulation check course of for low-level grouting filling

Firstly, the gangue from the coal washing plant is crushed into powder with a sure particle dimension and added with water and components to supply a 70.0% focus of gangue slurry on the concrete mixing station, the ratio of gangue, water, and components is 35:14:1. Secondly, the slurry is repeatedly transported by concrete tank vehicles to the neighborhood of the native collapse zone accumulation mannequin of the gangue yard. Finally, the slurry contained in the tank vehicles is pumped by pipelines to the simulated goaf for grouting and filling.

Simulation check evaluation of low-level grouting filling

From on-site statement and monitoring information, it may be seen that the move and diffusion of gangue slurry within the gaps between rock blocks within the simulated caving zone have the next traits:

-

(1)

The move of gangue slurry within the gaps between rock blocks is selective. When the dimensions of the hole between rock blocks is larger than 3–4 occasions the utmost particle dimension of the amassed gangue slurry, the gangue slurry is distributed within the gaps between surrounding rock blocks. When the dimensions of the rock block hole is lower than 3–4 occasions the utmost particle dimension of the amassed gangue slurry, there is no such thing as a or a small quantity of gangue slurry within the rock block hole close to the rock block hole.

-

(2)

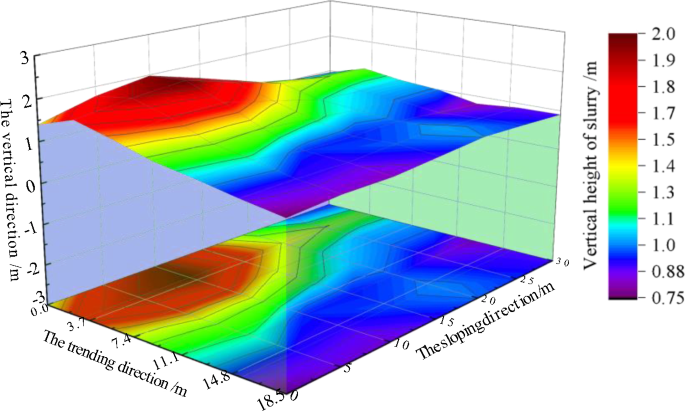

Starting from the outlet of the grouting pipeline, the general vertical peak of the gangue slurry removed from the outlet level reveals a downward pattern, with the downward pattern within the path of inclination being considerably better than the downward pattern within the path of strike. The most vertical peak of the slurry is 2.0 m, and the horizontal distance from the pipeline outlet is 0.4 m. The minimal vertical peak of the slurry is 0.75 m, and the horizontal distance from the pipeline outlet is 25.4 m. The gangue slurry is vulnerable to type slurry accumulation factors on the dip and strike boundaries, and the utmost accumulation quantity is on the intersection of the strike and strike boundaries, as proven in Fig. 6.

-

(3)

Along the move path of the gangue slurry, the proportion of coarse particles within the gangue slurry reveals a lowering pattern, whereas the proportion of nice particles reveals an rising pattern, the mass fraction of the gangue slurry additionally reveals a lowering pattern. And because the goaf deepens, the proportion of coarse particles within the gangue slurry decreases, and the mass fraction of the gangue slurry additionally decreases.

Engineering check of low-level grouting filling

Determination of slurry filling mannequin in Dahaize Coal Mine

According to the present situations of the mine and the choice means of the slurry filling know-how mode, the crushing system, pulping system, and pumping system are respectively organized on the bottom and underground close to the No. 1 blanking gap. The low-level grouting filling mode is shaped within the goaf behind the 20101 working face in panel 201. Then the bottom and underground coordinated pulping and low-level grouting filling are established to discover the cheap parameters of slurry filling know-how of Dahaize Coal Mine and supply information assist for the following system growth and reconstruction.

Engineering check course of for low-level grouting filling

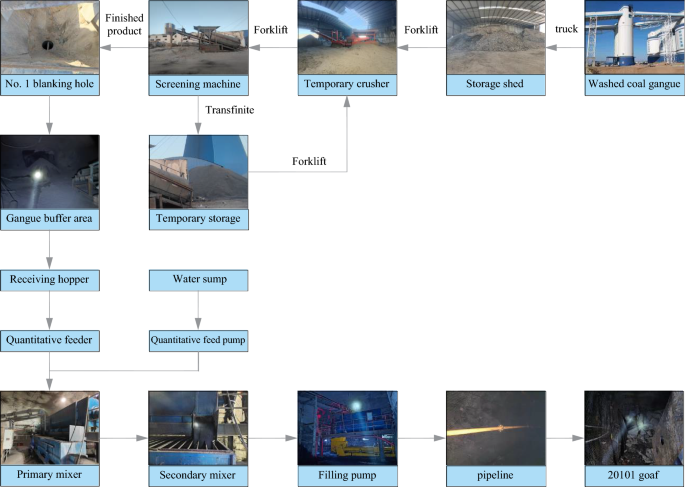

Because this check wants to make use of the forklift to switch gangue, and the surge buffer has not been arrange, its front-end crushing and back-end pulping techniques can not work repeatedly, so this check course of is described by subsystem. Its check course of is proven in Fig. 7.

Process of a crushing system: the truck is used to move the gangue of −50 mm within the gangue bin of the coal washing plant to the gangue boron storage close to the No.1 blanking gap of the commercial website. Then the forklift is used to switch the gangue to the crusher for crushing. The crushed gangue is then transferred to the screening machine by the forklift for screening. The completed particle mixture beneath the display screen is instantly put into the underground buffer by the No.1 blanking gap. The massive particle mixture on the display screen is unloaded to the bottom. It is transferred to the crusher by forklift for additional crushing.

Process of pulping and pumping system: through the filling operation, the forklift transfers the completed particle mixture buffered on the backside of the No. 1 blanking gap to the receiving hopper. Then, the quantitative feeder beneath the receiving hopper and the quantitative feed pump of the clear water silo transport the completed particle mixture and mine water to the first mixer at a ratio of seven:3 for pulping, and the certified, ready slurry flows robotically to the secondary mixer for buffer mixing. Then it flows robotically to the slurry receiving hopper within the filling pump. Finally, the filling pump will fill the gangue slurry within the slurry receiving hopper to the caving zone of the goaf behind the 20101 working face by low-level grouting by the south wing return air predominant roadway pipeline and 20101 return air roadway pipeline.

Design of engineering check parameters for low-level grouting filling

The filling materials of coal gangue slurry consists of coal gangue and mine water, and the coal gangue is the principle mixture of the filling materials. Based on low-level grouting filling simulation check and a number of on-site assessments and debugging, this engineering check eliminated the gangue with a particle dimension better than 3 mm, leading to a median proportion of 26.32% of the 1.25–3 mm particle mixture, 53.03% of the 0.075–1.25 mm particle mixture, and 16.74% of the 0–0.075 mm particle mixture. The ratio of gangue slurry is coal gangue to mine water = 7:3, and the mass fraction of gangue slurry is 70%.

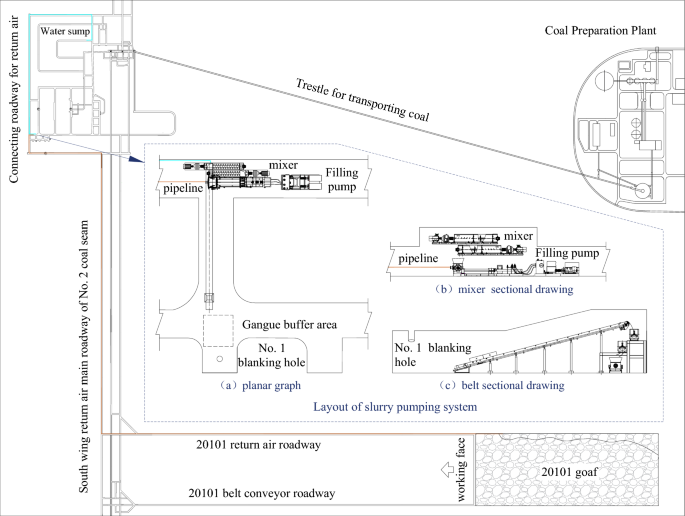

The grouting pump used on this experiment is a plunger pump, with a most theoretical supply capability of 200m3/h on the outlet and a most theoretical supply strain of 14.0 MPa on the outlet. The underground pipeline mannequin is φ133 × 12 mm, organized in sequence on the backside of the north and south wing return air connecting roadway, No.1 return air shaft, south wing return air predominant roadway, and 20101 belt conveyor roadway, with a complete size of roughly 4000 m, as proven in Fig. 8.

Based on the experimental situations and supporting gear of this check, the important move charge for low degree grouting filling within the return air roadway of Dahaize in 20101 was calculated in response to the components of Changsha Research Institute of Mining and Metallurgy:

$$V_{c} = 2.809left( {frac{{rho_{s} – rho_{h} }}{{rho_{h} }}} proper)^{ – 0.308} C_{V}^{ – 0.308} D^{0.31}$$

(1)

In the components, VC is the important move charge for slurry transportation, m/s. ρS is the density of gangue, kg/m3. ρH is the density of water, kg/m3; CV is the amount fraction of the gangue slurry. D is the inside diameter of the pipeline, m.

After calculation, the important move charge for low degree grouting filling is 1.71 m/s. Based on 1.1 occasions the important move charge, the design move charge for slurry transportation shouldn’t be lower than 1.88 m/s, and the design move charge shouldn’t be lower than 63.12m3/h.

Analysis of engineering check impact of low-level grouting filling

The Dahaize Coal Mine adopted a coordinated association system above and under the shaft and a low degree grouting filling technique to conduct a coal gangue slurry filling check within the goaf. Without affecting the traditional manufacturing of the working face, the washed coal gangue was efficiently crammed into the collapse zone of the underground goaf. In the low-level grouting filling check, the pump strain of the grouting pump is round 8–10 MPa, and the transportation state of the gangue slurry pipeline is secure. The common transportation move charge is about 1.94 m/s, and the low-level grouting filling is carried out at a median interval of 30 m. The single filling quantity of coal gangue is between 150 and 600 t.

[adinserter block=”4″]

[ad_2]

Source link